views

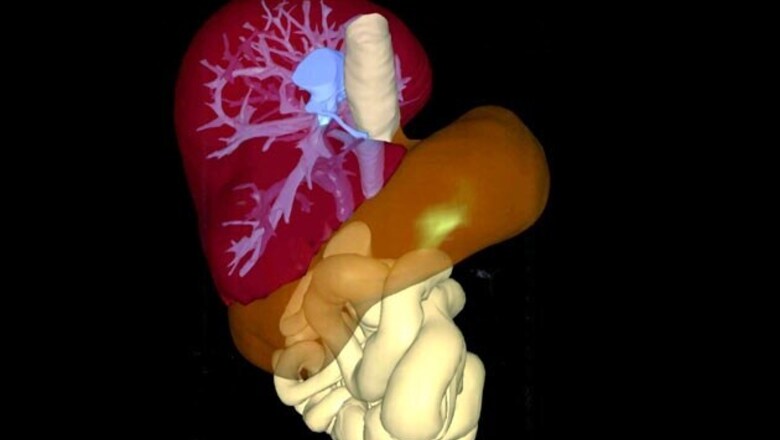

London: Scientists have created a 3D printing device that could soon be used to make tailor-made transplant organs at the click of a button.

The breakthrough by British experts involves a special print head nozzle that can dispense a wide range of different materials highly accurately.

The nozzle, called the Vista 3D, can print large particles and fluids through improvements in droplet ejection, opening up the possibility of printing products as diverse as toys, medical devices, aircraft parts and even organs.

Sam Hyde, managing director of the company Melbourn TTP, said the medical possibilities were "very exciting."

Speaking to 'Cambridge News', Hyde said organ-printing could be done in just five to 10 years' time.

"You need to get the right kind of cells to the printer and keep them in the right condition. The key thing is then to delicately dispense these cells into the right position without damaging them, and our technology is very good at that," he said.

In the shorter term, the printers could make simpler structures, such as highly customised surgical implants, orthopaedic implants, or hip replacements - possibly taking the tailor-made designs from an MRI scan.

The nozzle will be fed by cartridges of the required material, which could be anything from stem cells to metal powder.

Dr Sean Cheng, an expert in medical devices at Cambridge University, said if all goes to plan, printing organs "would literally save hundreds of thousands of lives every year."

However, there remain several steps before the technology can be used. The special nozzle is currently fitted onto 2D printers but upgrading it to 3D printers could take two years, Hyde believes.

Comments

0 comment