views

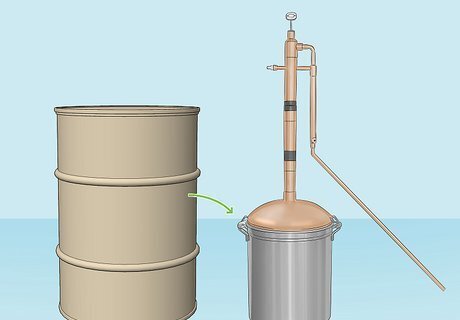

- Apply for a permit before making ethanol at home. In the meantime, pick up a 55 US gal (210 L) steel drum, a hydrometer, and a reflux still to distill your ethanol.

- The main component of ethanol is fruits or vegetables. You’ll need roughly 56 pounds (25 kg) of fruits and vegetables to make 2.8 gallons (11 L) of ethanol.

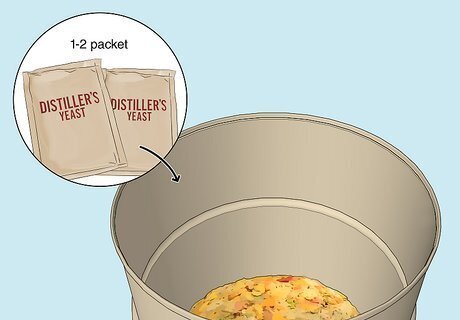

- Mash the fruits or veggies, cover them with water, add 1-2 packets of distiller’s yeast, and wait 7-10 days for it to ferment.

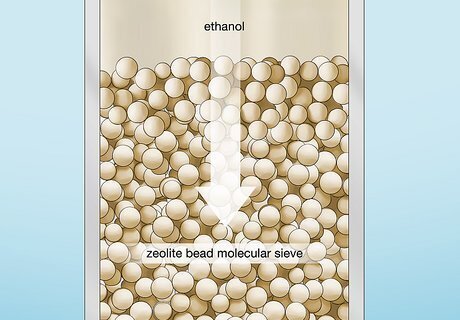

- Dump your fermented mash into the still, heat it up, and then filter the water and contaminants out with a zeolite bead molecular sieve to make your ethanol fuel.

Processing Your Raw Biomaterial

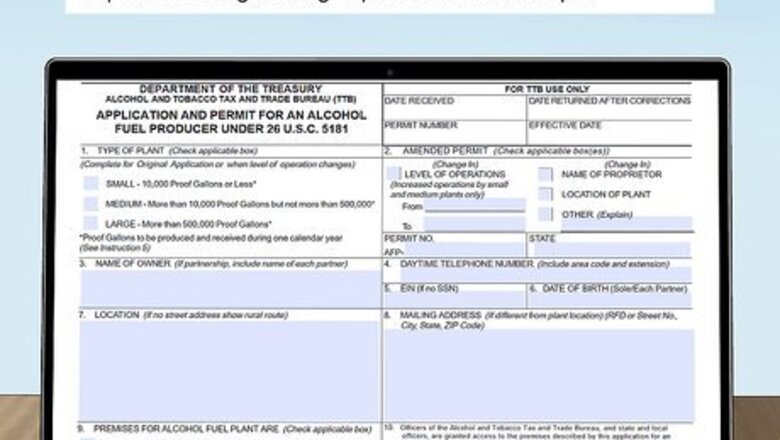

Apply for authorization to produce ethanol legally. In order to make ethanol, you need written permission from the proper agency. If you live in the United States, fill out the producer request form online and submit it electronically to the Alcohol and Tobacco Tax and Trade Bureau (TTB). If you're approved, you'll receive a document giving you the go-ahead to ferment and distill ethanol at home. If you live outside of the US, contact the governing body that oversees alcohol-related laws in your area for more information on how to legally produce ethanol. As an approved ethanol producer in the US, you'll be permitted to make up to 10,000 proof-gallons of ethanol per year. Unless you’re a convicted felon, anyone can apply to make ethanol fuel. There are no unique requirements.

Gather old fruits and vegetables for fermentation. Any fruit or veggie that is slightly past its prime will work, although the sweeter and higher the sugar content, the better. Commercial-grade ethanol is most commonly made from corn, but you can get the same result using just about any type of produce with a naturally high sugar content. Check with your local grocery store or farmer's market to see if they have any spoiled produce you can take off their hands for free. If you farm or grow your own food, start holding on to any inedible, spoiled, or unusable crops. Items like apple, bananas, pineapples, peaches, potatoes, and sugar beets are higher in sugar than other varieties of fruits and veggies, and therefore tend to give off more natural ethanol.

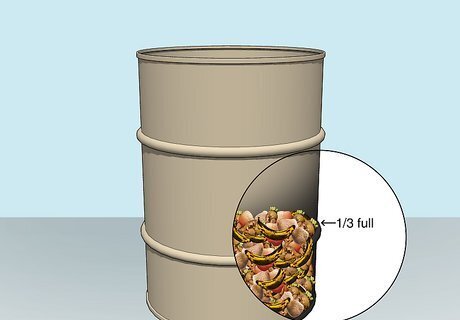

Fill a barrel or similar container with your rotten fruits and veggies. Add your fruit and veggies until the drum is about ⅓ of the way full. Be careful not to fill your container more than halfway or it may overflow during the fermentation process. You’ll need roughly 56 pounds (25 kg) of fruits and vegetables to make 2.8 gallons (11 L) of ethanol. If possible, use a standard 55 US gal (210 L) steel drum. One of these will offer plenty of room and won't leach harmful contaminants into your fuel as it ferments. If you can't find a steel drum, a simple wooden or plastic barrel will work just fine.

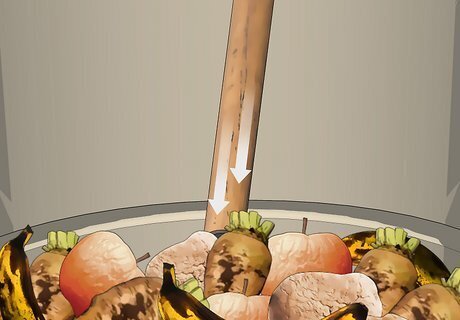

Mash the fruits and vegetables thoroughly with a blunt object. Use a broom handle, potato masher, wooden dowel, or similar item to churn and compact your biomaterial until it forms a thick, goopy mixture with a uniform texture. This mashing releases the natural sugars and creates room to add the other necessary ingredients. Keep mashing your fruits and veggies until there are no large chunks remaining. It may take a while and it may be exhausting, but you really need to break everything down. Rotten produce tends to smell pretty unpleasant. Be sure to work in a well-ventilated area, and consider covering your face to cut down on noxious odors. If you’re a farmer with access to a hammer mill or roller mill, just pour the veggies and fruits into that.

Fermenting Your Fruits and Veggies

Mix 1-2 packets of distiller's yeast in with your biomaterial. Snip each packet open and sift the powdered yeast into your fermenting container. Then, churn the mixture again until the yeast is evenly distributed throughout. The yeast is the key ingredient needed to kickstart the process of fermentation. As a general rule, use 1 packet of yeast for every 20 pounds (9.1 kg) or so of biomaterial. The yeast will continue to help ferment over time, but if you use a small amount, it will take forever. Distiller's yeast is a special type of yeast that's resistant to alcohol (ethanol is a type of alcohol, just FYI), which makes it perfect for making ethanol.

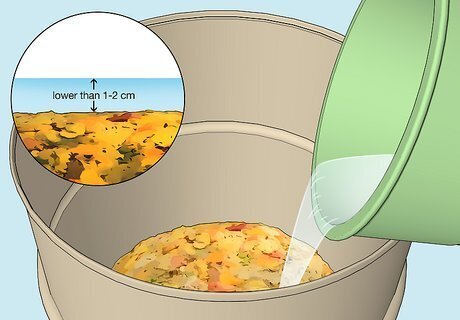

Add clean, room temperature water to the top of the mixture. The exact proportion of water you use will vary depending on the amount of biomass you're working with; add enough water to cover your biomaterial and keep it moist. Keep the water lower than 1–2 centimetres (0.39–0.79 in) above the contents of the container. Use distilled or filtered water, if possible. Ordinary tap water may introduce unwanted chemicals or impurities into your batch of homemade ethanol.

Cover your fermenting container to keep it airtight. If you're using a barrel or drum that came with a removable lid, simply put the lid in place. Close off makeshift containers by fitting a plastic garbage bag upside down over the opening and taping around the upper edge to prevent air from getting inside. In order for your raw biomaterial to ferment successfully, it's important to make sure that your container has been properly sealed so that no foreign contaminants interact with the yeast.

Allow your biomaterial to ferment for at least 1 week. In most cases, it will take somewhere between 7 and 10 days for the sugars in your fruits and veggies to break down completely. During this time, avoid opening the container for any reason unless you’re checking in to measure the sugar content of the biomass. As your raw biomaterial sits, the yeast will feed on its natural sugars and leave alcohol behind. This alcohol can be distilled into ethanol!

Use a hydrometer to check the sugar contents of your biomaterial daily. Open your fermenting container and insert the tapered end of the hydrometer into the liquefied biomaterial. The sugar reading (most often denoted in ounces per gallon, “Bx” “Balling,” or “Brix”) will decrease every day. The fermentation process is complete after 7-10 days when you get a reading of 0 the fermentation process is complete. Your biomaterial may ferment in more or less time, so keep an eye on the sugar content rather than following a set timetable.

Distilling and Blending Your Ethanol

Transfer your biomaterial to a reflux still for distilling. Move the mixture over as soon as your hydrometer shows that all the sugar has been converted to alcohol. The longer you delay, the more likely it will develop bacteria. Carefully pour the mash directly into the opening column for your feed mixture. In some cases, you may also be able to rent equipment like reflux stills for a low daily or weekly rate. Check with home brewing and distilling companies in your area for more info.

Heat the biomaterial in your still to separate the water from the ethanol. Different stills work differently, so be sure to follow the instructions included with your still exactly. In general terms, you turn a burner on under the column, which causes the fermented liquid to evaporate into steam. This steam pulls through a special filter before settling in the smaller container in the form of semi-pure ethanol. Keep in mind that a container full of biomaterial will only produce a small amount of pure ethanol. In fact, it takes about 56 pounds (25 kg) of fruits and vegetables to make 2.8 gallons (11 L) of ethanol!

Filter the remaining water out of the ethanol with zeolite. The liquid that comes out of the still isn’t 100% pure ethanol. There are still trace elements and water droplets in the ethanol. To remove them, pour your ethanol through a zeolite bead molecular sieve. The beads will absorb the water and contaminants while leaving the ethanol in liquid form. Pure ethanol should be 100% clear. You may need to filter the ethanol multiple times depending on how dirty it is. You now have pure ethanol!

Combine 85% purified ethanol with 15% gasoline to make E85 fuel. This is the standard ratio used to turn pure ethanol into a reliable fuel source. Mix the 2 liquids in a clean gas can or similar container, and seal it for storage. Once you've blended your ethanol with gasoline, you won't be able to use it for any purpose other than fuel. You can use this fuel in lawnmowers, tractors, leaf blowers, and other small engines that run on gas, but don’t put it in your normal vehicle. E85 will damage unmodified engines if you don’t drive a flex fuel vehicle. Refer to your vehicle’s user manual for more info. To prevent accidents, store your homemade ethanol fuel at room temperature in a well-ventilated space. You could add a few drops of ethanol to DIY cleaning products to make them more effective as a sanitizer. Ethanol is also used as a food additive, but it’s not safe to consume DIY ethanol that hasn’t been tested for safety reasons.

Comments

0 comment