views

Assembling the Suit Panels

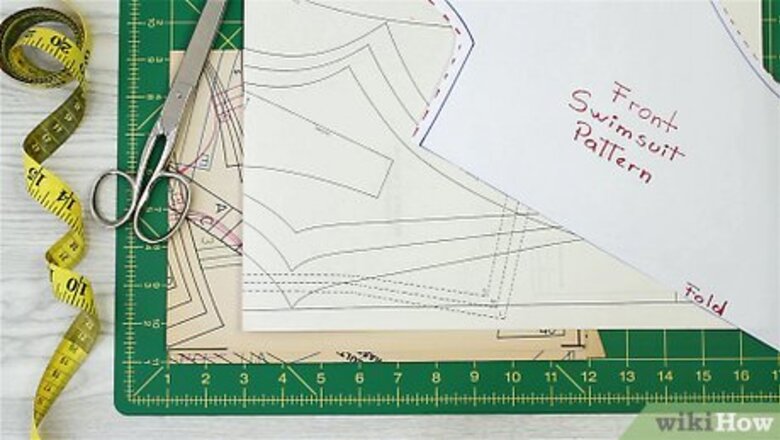

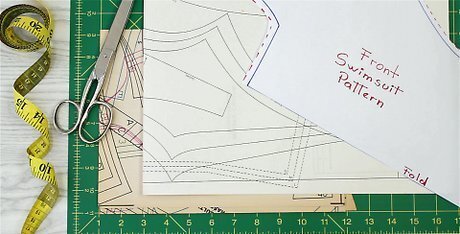

Buy or make a 1-piece swimsuit pattern, front and back. It’s easy to find swimsuit patterns online or in craft stores—they’re made of paper, and each panel (front and back) looks like that side of the suit if you cut it in half vertically. Alternatively, make your own pattern by folding a swimsuit in half vertically, tracing its outline on craft paper, then folding it vertically the other way and tracing it on another sheet of paper. Pre-made patterns have guidelines so you can slightly reduce the size or cut of the suit as desired. If you make your own pattern, you can easily add to, cut from, or subtly adjust the shape or style of the suit. Swimsuits are stretchy and should have “negative ease”—the pattern you choose should have measurements that are about 3–5 in (7.6–12.7 cm) smaller than the body measurements of the person you're making the suit for.

Get swimsuit and lining fabrics and swimsuit elastic. Be sure to buy a fabric that’s specifically for swimsuits and has 4-way stretch—it stretches easily both vertically and horizontally, unlike a 2-way stretch that only stretches easily horizontally. For the lining, get either swimsuit lining fabric or a neutral-colored swimsuit fabric, once again with 4-way stretch. Also buy a roll of swimsuit elastic (not standard elastic). Swimsuit fabric is typically composed of around 80%-90% nylon and 10%-20% lycra or spandex. It’s okay to use 2-way stretch fabric for 2-piece swimsuits, while 4-way stretch is a great choice for 2-piece suits and necessary for 1-piece suits. Otherwise your 1-piece suit won’t be stretchy enough to pull on! Swimsuit elastic is designed to hold up better to chlorine and saltwater, and is usually made of cotton and/or rubber instead of polyester.

Lay out and fold over 2 pieces each of swimsuit and liner fabric. Lay the 2 pieces of swimsuit fabric design-side down and smooth them out. Fold each piece in half like you’re closing a book, creating a straight fold line along one edge. Do the same thing with the lining fabric (keeping in mind that it doesn’t have a design side). When folded in half, each piece of fabric needs to be slightly larger than your swimsuit pattern panels.

Use the patterns to trace and cut the swimsuit panels. Lay the front and back panel patterns onto their respective pieces of swimsuit fabric, placing the straight edge of the pattern (that runs from the neck opening to the crotch) right on top of the folded edge of the fabric. You have 2 options at this point: trace the pattern onto the fabric with chalk, then cut it out; or, just follow the outline of the pattern with sharp scissors or a rotary cutting wheel. Repeat the process with the lining fabric. Don’t stretch the fabric while you cut it. Use pins or fabric weights (small weighted discs), if desired, to help keep the pattern in place while you trace and/or cut.

Unfold and lay out the cut panels so they’re inside-out. In other words, unfold and lay out the back panel of the suit material on your work table with the patterned side facing up, then lay the front panel on top of it with the patterned side facing down. Make sure the unfolded panels are smoothed out and lined up, especially at the shoulder straps, sides, and crotch area. Do the same thing with the front and back liner panels, although in this case there’s no “right” and “wrong” side of the fabric to worry about!

Sew the tops of the straps, the sides, and the crotch with a zig-zag stitch. Use either ballpoint or stretch needles in your sewing machine and set it to apply either a regular zig-zag, three-stretch zig-zag, or lightning stitch. Focus on sewing together 3 areas right now: the tops of the shoulder straps; the sides of the suit, between the arm and leg openings; and the crotch area between the leg openings. Repeat the step separately with the front and back liner panels. You’ll attach the suit material and lining material shortly. Zig-zag sewing patterns hold up much better to stretching. Use a polyester or wooly nylon thread. Cotton thread isn’t stretchy enough and doesn’t hold up as well to chlorinated water or saltwater.

Baste (temporarily stitch) the liner inside the swimsuit. Slip the liner into the suit material at the neck opening, then align the seams you just stitched in each—start with the crotch seam, then the side seams, then the strap seams. Pin the paired seams in place as you get them aligned. Set your sewing machine to do a simple up-and-down running stitch, which is a standard basting stitch. Baste the liner and suit at the neck, arm, and leg openings. Basting is also known as tacking. It’s not necessary to remove the basting stitches after you’re done with the suit in this case. If you choose to do so, however, wait until the suit is all finished, then use a seam ripper to slice through the basting thread and pull it out.

Adding Elastic to the Suit

Sew swimsuit elastic into the neck opening with a 25% stretch. Turn the suit inside-out and hold the end of the elastic strip to the inside of the middle back of the neck opening. Add 5-10 zig-zag stitches with your sewing machine to hold the elastic in place. Grasp the elastic about 4 in (10 cm) down the strip and stretch it to 5 in (13 cm)—this is a 25% stretch. Zig-zag stitch the stretched section of elastic to the inside of the neck opening, then grasp the elastic further down the strip and repeat the process. Keep doing this until the elastic runs all the way around the inside of the neck opening. Stretch only the elastic strip, not the swimsuit or liner fabric.

Add elastic to the arm openings, again at a 25% stretch. Use the same procedure as with the neck opening, starting at around the middle of the rear side of the shoulder strap. Continue stretching, zig-zag stitching, and repeating until you’ve gone all the way around each arm opening. Remember to stretch only the elastic, not the suit fabric, while stitching the elastic into place. Yes, sewing on the elastic is one of—if not the—trickiest part of making the swimsuit. But the elastic is more forgiving than you might think—you don’t have to maintain exactly a 25% stretch—and it’s fairly easy to undo and redo any major mistakes. So keep at it with confidence! EXPERT TIP Shaelynn Haning Shaelynn Haning Professional Tailor & Business Owner Shaelynn Haning is a Tailor & Business Owner based in Tulsa, Oklahoma. Shaelynn is the founder of the highest-rated and most-reviewed alterations and tailoring service in Oklahoma, Tallgrass Tailor, employing a team of skilled craftsmen and women from across the country and the world. Shaelynn is a member of the State of Oklahoma Education Careers and Technologies Board and a member of both the Custom Tailors and Designers Association and the Association of Sewing and Design Professionals. She is the host of The Sew Show with Shae, an entertaining and educational sewing channel posting weekly videos on YouTube. Shaelynn earned her BS in Apparel Design and Product Development from Marist College. Shaelynn Haning Shaelynn Haning Professional Tailor & Business Owner Stretchy fabrics need practice and patience. Sewing a swimsuit with stretch fabric is hard and takes patience. The concept of negative ease — cutting it smaller to stretch and fit to the body — is key. First, practice on the sample fabric to perfect the close fit before using the final material. This care ensures the best outcome since stretch fabrics are unforgiving.

Sew elastic onto the leg openings at both 25% and 75% stretch. For the leg openings, you want the elastic on the rear side to be more tightly scrunched together. Start just in front of the seam at the crotch and sew halfway around the leg opening (on the front side of the suit) at a 25% stretch. Then, to go the rest of the way around (on the rear side of the suit), pull the elastic to approximately a 75% stretch—for example, stretch a 4 in (10 cm) length of elastic to 7 in (18 cm).

Load a second thread and twin needle for topstitching. Use your machine’s included adaptor to stack a second spool of thread on top of the first. Then, guide the second line of thread through the machine to load it, just like you do with a single line. Replace the single needle in the machine with a double needle and attach both lines of thread to it. Look for twin needles anywhere sewing supplies are sold. They look like little 2-tined pitchforks! Twin needles create 2 parallel lines of stitching that provide both strength and a finished appearance.

Topstitch the elastic bands into the suit with the twin needle. With the suit right-side out, fold over the edge of the fabric where it’s attached to the elastic band. Hold the folded fabric smooth and taut with your fingers as you run it through the machine, securing it with a zig-zag stitch or another type of strong yet flexible finishing stitch. Continue the process on all the areas of the suit with elastic. This is the finishing stitch for the suit, so congratulations! Don’t stretch out the elastic as you secure the topstitch in place. Just pull it slightly taut to smooth out any wrinkles or bunching. Topstitching the elastic bands helps secure them in place and makes the suit more comfortable to wear.

Comments

0 comment