views

Locating an Exhaust Leak

Park the vehicle on a level surface. In order to repair an exhaust leak, you will need to jack the vehicle up to locate it. Always jack vehicles up on flat, level surfaces to ensure the jack won’t topple over as you lift the vehicle. It is also important to ensure the surface is sturdy enough to support the weight of the vehicle beneath the jack. Black top or concrete are the best surfaces to jack up a vehicle on. Never jack up a vehicle on an uneven surface or the car may fall off of the jack.

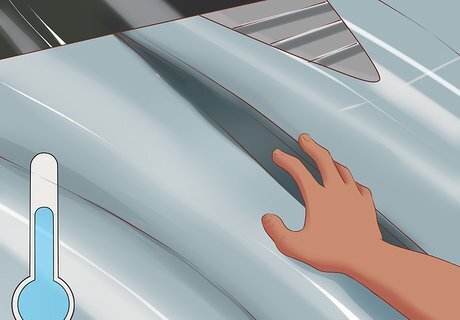

Wait for the exhaust to cool. You won’t be able to work on the exhaust pipe of your vehicle until it has cooled down for a while. The exhaust gas that travels through the exhaust piping is extremely hot while the engine is running and it could take hours for the metal to cool enough to touch. Wait for a few hours then place your hand near the exhaust pipe to see if you can feel any heat radiating off the metal. Touch the hood of your car. If it is still warm, the engine and exhaust are both still extremely hot.

Jack the vehicle up. Once the exhaust is cool enough to work on, slide a scissor or trolley jack under one of the vehicle’s rear jack points. Once in place, either lift and lower the handle (trolley jack) or turn the handle (scissor jack) to jack the car up. Place jack stands beneath the vehicle to support its weight once it is jacked to the appropriate height to work on the exhaust pipe. Never work beneath a vehicle without jack stands in place.

Inspect the exhaust piping. If you aren’t able to easily identify the leak in the exhaust pipe, use the vantage point you gained jacking up the vehicle to visually inspect the piping and muffler. Look for signs of damage that may indicate a leak such a deep rusting, cracks, scrapes or holes. Bottoming a vehicle out can cause exhaust leaks by scraping on the road or puncturing the piping. Rust can cause serious exhaust leaks if allowed to penetrate all the way through the steel.

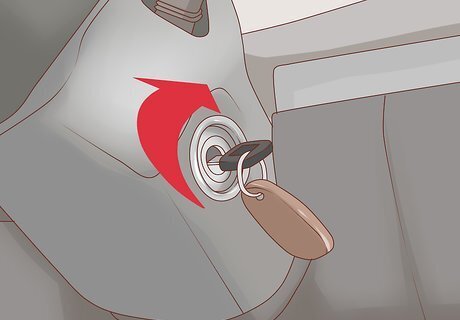

Start the engine to help locate leaks. If you can’t find the leak in the exhaust pipe with a visual inspection, leave the vehicle jacked up and start the engine. With the engine running, you should be able to quickly and easily identify the source of the leak. Keep your hands away from any moving parts while working beneath a vehicle with the engine running. Make sure the vehicle is in park (for automatic transmissions) or is in neutral with the wheels chocked (standard transmissions) before starting it while jacked up.

Determine the best way to repair the damage. If your exhaust pipe is severely rusted or has suffered extensive damage, it likely cannot be repaired and instead will need to be replaced. However, if the issue is a small leak or damaged muffler, you can patch the leak or replace the muffler using common hand tools. Small leaks can be repaired using exhaust tape or repair epoxy. Seriously damaged exhausts may need to be cut off and replaced completely by a mechanic.

Patching a Leaky Exhaust Pipe

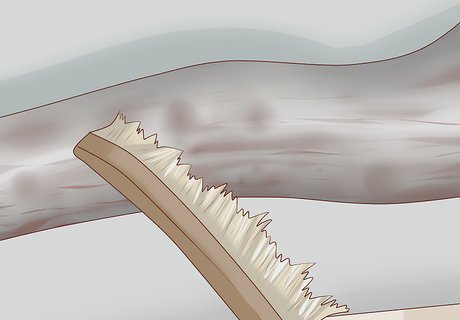

Scrub around the hole with a steel toothed brush. You won’t be able to identify the size of the leak or effectively repair it until you remove all of the road grime, dirt and rust from the pipe around the hole. Use a steel toothed brush to scrub away the grime, being careful not to get any in your eyes. Scrub the pipe all around the leak, including the top side if you can reach it. Make sure to wear eye protection when scrubbing the piping to prevent anything from getting in your eyes.

Prepare the surface of the pipe with sandpaper. Sandpaper will remove any last bits of dirt and debris stuck to the pipe while scoring the steel surface to better stick when you apply the patch. Rub 80 or 100 grit sandpaper back and forth along the exhaust pipe around the leak you intend to seal. If you are using exhaust tape, make sure to scrub the top of the pipe as well. Roughing up the surface of the metal will create a stronger bond for the patch.

Wipe acetone on the pipe around the leak. Acetone will ensure the metal is clean and free of anything that could interfere with the seal created by the exhaust tape or epoxy. Acetone is the primary ingredient in nail polish remover, so you may use nail polish remover for this step if you’d rather not purchase acetone strictly for this project. Be careful not to drip acetone in your eyes or mouth while cleaning the pipe with it. You can purchase acetone in the cleaning chemicals section of many retail stores.

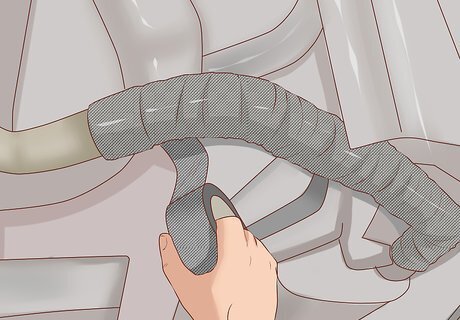

Wrap exhaust tape around the leaking portion of the pipe. If you are using exhaust repair tape, wrap it all the way around the part of the pipe with the leak. Continue to wrap the tape around the pipe for a few inches to either side of the leak to ensure there is a good seal. Different kinds of exhaust repair tape will require different application methods, so be sure to read the instructions before you get started. Some exhaust repair tape needs to be applied to warm pipes, so you may need to start the vehicle and let it run for a few minutes before applying. You can purchase exhaust repair tape at most auto parts stores.

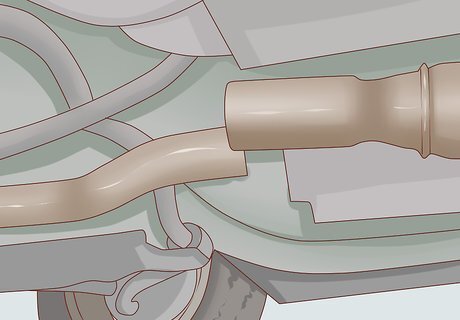

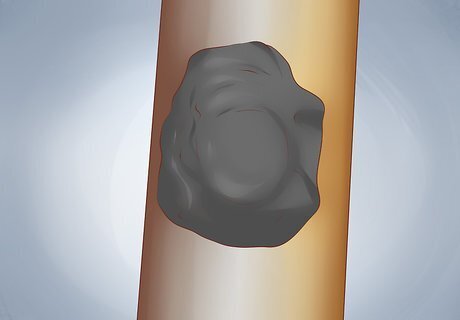

Apply epoxy to the leak. If you are using an epoxy to seal the leak, mix the two chemicals together using a wooden dowel. It will begin to cure immediately, so apply it directly to the leak as soon as the components are thoroughly mixed. Dab the epoxy onto the leak, then use the wooden dowel to spread it around the area. Make sure to cake the epoxy over the leak and surrounding pipe so it creates a thick film on the whole area. You may also choose to wrap the leak in exhaust repair tape after applying the epoxy. Different types of epoxy have different curing rates, so read the instructions on the package to know how long let the epoxy dry.

Replacing Your Muffler

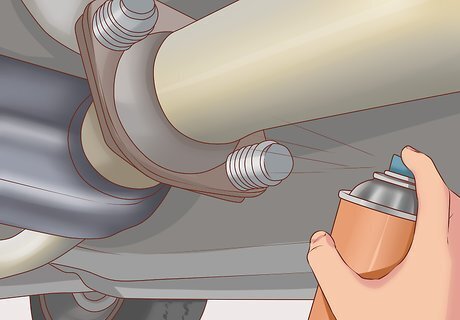

Spray rust penetrator on the exhaust clamps. If your muffler is not welded in place, it will be secured using muffler clamps. Spray a rust penetrator like WD40 onto the fastening hardware to break through some of the rust and grime that may have seized the nuts in place. You may need to spray the bolts and let them sit a few times before they are able to be loosened. You can purchase rust penetrator at most auto parts or large retail stores.

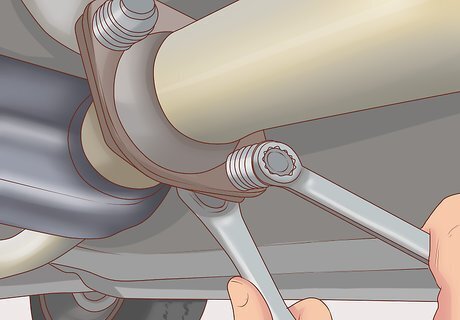

Loosen the exhaust clamps with a wrench. Once the fasteners have been thoroughly soaked in rust penetrator, use a wrench to remove the nuts holding the exhaust clamp in place. Make sure to use a socket or wrench of the correct size, as exhaust fasteners are prone to stripping or breaking. If you intend to reuse the muffler clamp, you may want to spray it with more rust penetrator as you work it loose. You can purchase replacement muffler clamps at most auto parts stores if they are too rusty to be reused.

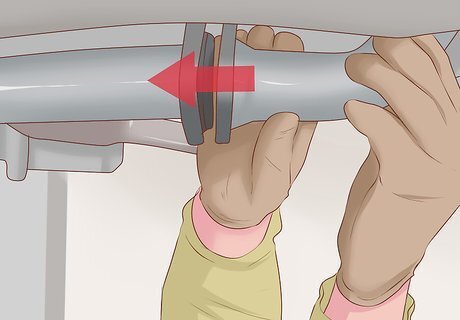

Slide the exhaust and muffler apart. Because the muffler and the piping have been held together with the exhaust clamp for so long, they may not come apart easily once the clamp is removed. Spray some rust penetrator where the two pipes meet and try to work them away from one another until they slide completely apart. If the pipes are rusted together, you may have to cut the pipes apart. If your muffler was welded in place, you will have to cut the pipes apart.

Hang the new muffler on the mounts. The muffler will have metal prongs sticking out of the top that slide into rubber eyelets below the body of the car. You may have to push the prongs through the rubber with a bit of force to get past the initial ridge. The rubber will prevent the muffler from rattling inside the cabin of the vehicle once the muffler is completely installed. There should still be enough play in the rubber mounts to allow you to move the muffler around as you connect it to the exhaust pipe.

Spray exhaust sealant on the ends of both pipes. Spray exhaust sealant on the pipe coming from the exhaust and the pipe it will connect to on the muffler. This will help establish a seal between the pipes and prevent any exhaust from leaking at the joint. Refer to the instructions on the exhaust sealant to know how long to let it cure. You can purchase exhaust sealant at your local auto parts store.

Slide the exhaust pipes together. Slide the pipe from the muffler over the existing exhaust pipe. The muffler should rest directly below the rubber eyelets its mounted to, so the eyelet should hang straight up and down when the pipes are joined properly. If the two pipes feel loose or can be wiggled, you will need an adaptor to match the correct size. Most exhaust piping comes in two or two-and-a-half-inch diameters. You will not be able to seal the wrong size pipe onto another pipe, but adaptors for most diameters can be purchased at hardware or auto parts stores.

Secure the muffler clamps onto the pipe. With the piping seated properly, slide a muffler clamp over the area where the muffler pipe overlaps the other. Use a hand or socket wrench to tighten the clamp until it is not possible to move the pipes back and forth at all. You may want to use a half inch drive wrench to tighten the clamps to make sure you have enough leverage to tighten it sufficiently. Be sure you tighten the clamp where the piping overlaps, otherwise you may not create a solid seal.

Comments

0 comment