views

- Welding is the process of joining metals together using high heat to melt the parts and allowing them to cool to form one unified piece.

- Gas Metal Arc (MIG) and Stick (Arc) welding are the two most common beginner-friendly welding methods.

- Learn welding as a hobby by signing up for classes or workshops through your local welder, community college, or trade school. Use free online resources to further your studies.

Welding Overview

Welding is the process of fusing two or more materials with high heat. Welding can be performed on metal, thermoplastics, and even wood to make one unified piece. It is often used to construct buildings, bridges, vehicles, and art, like metal sculptures. There are many different types of welding, including: MIG Welding Stick or Arc Welding TIG Welding Plasma Arc Welding Electron Beam and Laser Welding Gas Welding Atomic Hydrogen Welding Oxy-Acetylene Welding

Stick or MIG welding are beginner-friendly options. Gas Metal Arc welding (MIG) and Stick welding, also called Arc welding, are the two most common and affordable welding methods. MIG consists of two types of welding; the first type uses bare wire, while the second uses flux core to join thin pieces of metal together. Meanwhile, Stick welding is considered the “old fashioned” way of doing things, as it uses a stick electrode welding rod to join pieces together. If you’ve already taken a course or class, stick with the welding technique and machine you’ve already used.

Basic Welding Equipment

Auto-darkening welding helmet The light that welding gives off is incredibly bright and can cause permanent damage to your eyesight. In addition to protecting your eyes, a full-face welding helmet will prevent sparks and metal debris from being shot into your face as you weld. Never weld a piece of metal without having full face and eye protection first. An auto-darkening welding helmet will prevent you from having to lift your helmet when you stop welding.

Heavy-duty welding gloves Thick leather welding gloves protect your hands from getting burnt while you weld. Before you purchase welding gloves, determine the kind of welding you want to do, then purchase gloves made specifically for that style. This information is typically found in the product description or within the product's name. For instance, MIG welding gloves are often thicker and provide less hand mobility than TIG welding gloves.

Fire-resistant leather apron Buying a leather apron that’s made for welding will protect your clothes and body from getting burned. Under your apron, wear a long-sleeved shirt with buttoned or closed cuffs, long pants, and closed-toe shoes or boots.

Welding machine Search online for different welding machines and read customer reviews to find a reliable brand and model you can purchase. Stick welders are typically the cheapest, while MIG welders are more expensive on average. Once you determine which machine you want, order it online or from a hardware store and bring it to your working area. The average stick welder will be anywhere from $75 - $400 USD. MIG welders typically cost anywhere from $100 - $1,000 USD. You can always look on online marketplaces for refurbished or used models that may be more affordable.

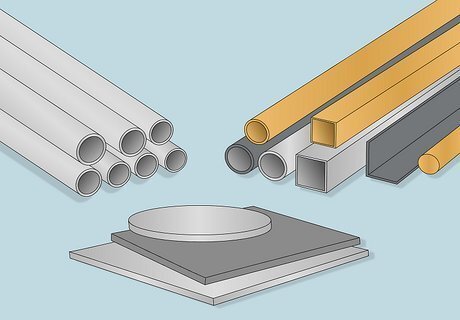

Welding materials Commonly used materials for welding include steel and stainless steel, aluminum, titanium, cast iron, copper, brass, and magnesium alloy. Each type of metal will respond differently and may be better suited for certain welding styles. For instance, steel, stainless steel, and aluminum are ideal for MIG and Stick welding. If you think it, you can make it. However, common welding items include fireplaces, coat hooks, wine bottle holders, bar stools, and storage racks.

Welding Resources

Look for welding classes at community and art centers. Search online or on your local community's or art center’s website to see if there are any introductory welding classes available. These courses will already have a workshop and equipment set up for you, so you don’t have to purchase it yourself, and will provide introductory instructions that can help you get started on your welding hobby. These courses can range anywhere from a day of training to 2-3 months of training. Ask for a class schedule before you sign up for the classes.

Contact a community college to see if they offer welding classes. Many community colleges, vocational schools, and some universities offer welding classes as part of their curriculum. If you are going to school or plan on going to school, search on the school’s website to see if they offer welding classes. Then, sign up for the class during your class registration period. You don’t need to obtain a college degree to learn welding. Contact your local community college or vocational school to find out if they have non-credited welding classes you can sign up for. You can receive a welding certification through the American Welding Society, which may be required for a career in welding. This can be obtained through a trade or vocational college.

Speak to local welders in your area if you can’t sign up for a class. If no community centers or schools offer welding classes, or you can’t afford them, local welders may be willing to show you the ropes. Search for welding or metal fabrication companies near you, and then call them and tell them that you’re interested in touring their workshop. Arrange a time and date to visit them, then express your interest while taking the tour. Welding and metal fabrication companies often offer free tours. If you want to learn how to weld, ask metal fabricators if you can apprentice or work as a fellow under them. Seeing welding in person will give you a better idea of whether it’s the hobby for you.

Watch video tutorials online to learn common welding techniques. You can use YouTube to provide supplemental knowledge for the classes that you’re taking or to learn different welding techniques. Because welding can be dangerous, practice under the supervision of an experienced welder before you start doing it yourself.

Read articles and books on how to weld. You can visit the American Welding Society’s website to read articles and publications on welding. If you want to enhance your knowledge of different welding practices and techniques, try these popular books: Welding: Principles and Applications by Larry Jeffus Audel Welding Pocket Reference by James E. Brumbaugh and Rex Miller Welding Essentials by William L. Galvery Jr. and Frank B. Marlow

How to MIG Weld

Work in a well-ventilated area and wear safety gear. Inhaling the noxious fumes from certain welding machines is dangerous and unhealthy. Open windows and doors to make sure that the room is well-ventilated. In addition, make sure to wear all safety gear before you start welding. To protect your eyes and face wear a welding helmet, hand shield, or goggles. Use fire-resistant ear muffs or plugs to prevent sparks from entering the ear. Use a respirator to protect your lungs from fumes and oxides and fire or flame-resistant clothing and aprons. Opt for rubber-soled safety shoes and insulated gloves to protect against electric shock and heat. Welding supplies can be purchased online or through your local hardware store.

Use 100% Argon or a mixture of CO2 and Argon (ArCO2) gas. Generally, a gas-shielded MIG welder is the standard machine that people use. Attach an ArCO2 gas tank by securing it to the side of the machine with a metal chain. Remove the tank’s protective cover, and attach the gas regulator flow meter by hand, tightening with a wrench. Then, screw the gas hose to the regulator and the MIG machine. Open the gas valve half-way. Set the flow rate to 20 Cubic Feet per Hour (CFH) while pulling the MIG’s trigger. You do not need gas to MIG weld. However, you’ll need to use a specific flux-cored filler wire instead of a gas tank. A shielding gas tank protects the weld pool (the dime-sized portion of a weld where the base has reached its melting point) from the atmosphere and similar outside contaminants.

Select the appropriate amperage output and wire size. When setting up your MIG welder, the material thickness you’re working with determines the amperage you need. Generally, each .0001 inch of material thickness requires 1 amp of output. From there, you can select the appropriate wire size. Typically, when working between 30 and 130 amps, you’ll use a .023-inch wire. Always consult your machine’s owner’s manual as it contains important information about operation and safety. When in doubt, you can consult online wire size charts to determine the amperage you need to work with.

Adjust the wire speed and voltage to make a consistent weld. Your machine determines your speed, the type of wire, and the metal thickness you’re welding. Generally, your machine will come with a chart, manual, or specification guide that you can refer to. However, it may be a game of trial and error. As you weld, listen for a consistent sizzle similar to the sound of bacon on a frying pan. That’s how you’ll know you’re welding a proper bead. If you weld cracks and spurts, adjust your settings. Typically, slower wire speeds work better on thinner pieces of metal. You can also consult online charts to determine the wire speed, which may require some math. For example, if you’re working with 130 amps, multiply 3.5 x 130 = 455 ipm (inches per minute) for the wire speed.

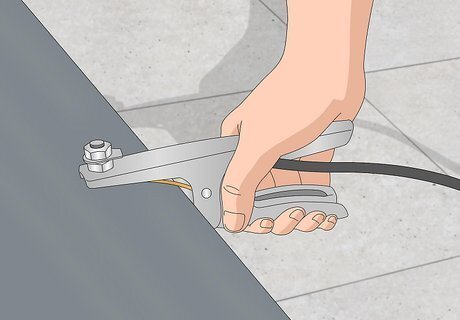

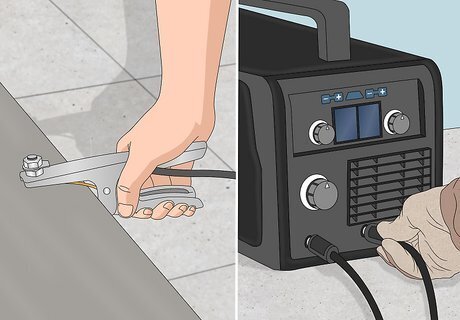

Attach the welder's ground clamp to your workstation. Grounding the welder is essential, or you may electrocute yourself as you weld. The ground clamp should be attached to a flexible hose coming from your welder. Attach the clamp to the table or workstation that you plan on welding on.

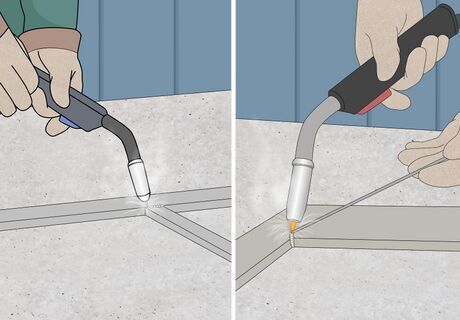

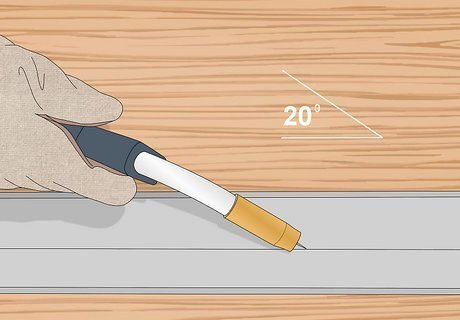

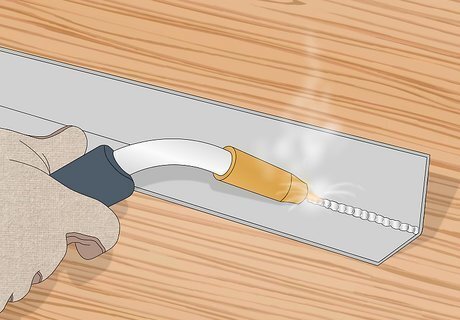

Position the tip of the gun at a 20-degree angle as you weld. Always hold your welding gun with both hands. Position the tip of the gun towards the metal at a 20-degree angle so that you can push the weld away from you. Pushing the trigger will feed the wire through the machine at a regulated rate and create the weld. If the welding machine isn't working properly, adjust the settings and try again. Remember to wear your welding gloves and safety goggles or a helmet so your skin isn’t exposed to sparks or heat.

Move your gun in tiny circles as you weld to create a bead. A bead is the proper weld shape and looks like tiny, overlapping circles. When you practice welding, make these tiny circles to create a bead instead of pushing the welding gun in a straight line.

Practice welding on scrap metal before you work on a real project. Practice running straight beads on pieces of scrap metal before trying to weld 2 pieces of material together for a bigger project. This will help you acclimate to the equipment, achieve straighter welds, and work out any kinks. Beginner Friendly Projects Ideas: A metal box, welding table, MIG gun holder, or a horseshoe dutch oven holder.

How to Stick Weld

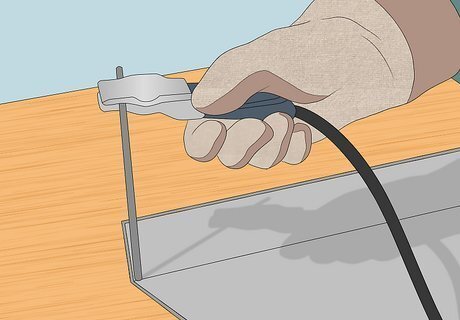

Attach the clamp and electrode holder to the machine. Hook the clamp, also known as the work lead, to the negative terminal. Then attach the clamp side to your work table. Then, hook the electrode holder into the positive lead (DCEP, which means Electrode Positive). This makes it easier for first-time welders to create a uniform bead as they begin to weld. If your machine has multiple functions for different welding types, like TIG, be sure to enter Stick mode. Stick welding doesn’t require gas tanks.

Set the amperage to the same level as your stick. The stick that attaches to your welding gun is an electrode, often called the “rod.” Different rods will have specifications on their packing or instruction manuals, explaining the proper amperage your machine needs. Generally, you’ll want to use: 40-80 amps for a 3/31-inch 6010 or 6011 Rod. 75-125 amps for a ⅛-inch 6010 or 6011 Rod. You can use an online stick welding calculator to plug in the material you’re working with and the type of electrode to get a suggested amperage range.

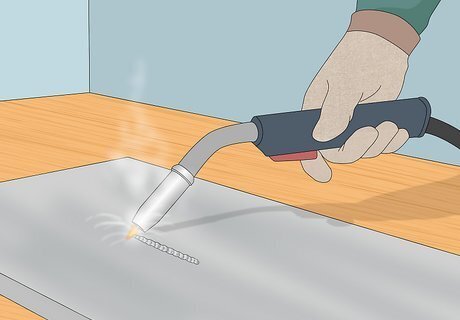

Tap your rod against metal to start it up. Tighten the electrode in the welding gun before you start. Lightly strike the rod against the metal like a match to start the weld. When it successfully starts welding, you'll see an electric arc coming from the electrode on your gun. Remember to wear a non-flammable apron, welding mask, and gloves before you weld.

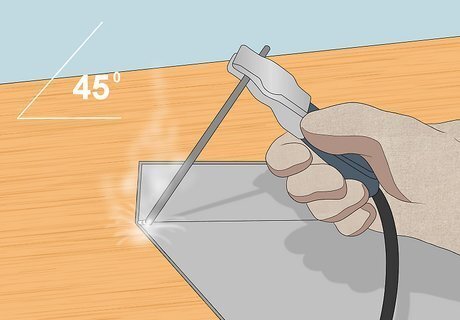

Position your rod based on your work angle. If you’re working with a 90-degree joint angle, position your rod at a 45-degree work angle, coming in with a flat or overhead fillet joint. For a 180-degree joint angle, use a 90-degree work angle to create a butt joint (where two pieces are joined together side by side). For a 90-degree lap joint angle (where two metals are overlapping), use a 60 to 70-degree work angle, using the road at a flat or horizontal angle.

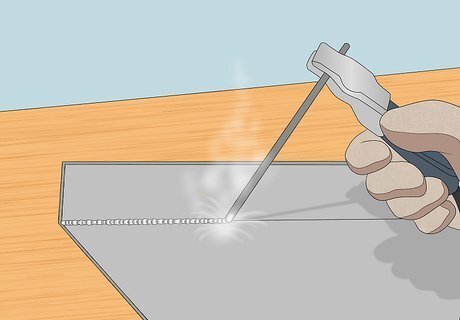

Drag the rod to weld. Unlike MIG welding where you’re working in semi-circles, with stick welding you drag or pull your weld. Place your stick into the joint at an angle, then tilt your stick slightly sideways by 10 to 15 degrees. Pull the rod at a consistent speed to weld the material.

Comments

0 comment