views

Check power source. Ensure that any electrical power fed into power cord, is shut off prior to working on motor.

Prepare power cord. Using a pair of diagonal cutters, cut and remove 3 in of rubber insulation around outside of power cord. Revealing four wires inside cord. Remove approx. 3 inches (7.6 cm) of insulation from the outside of the four lines located within the power cord. Once for inner lines are visible remove approx. 1in. of insulation from the red, white and black lines, revealing copper wire. Be aware that the power lines are referred to as: L1, L2, L3 respectively however there is no specific order to the power lines, meaning these tittles can be used interchangeably.

Connect ground wire to wire terminal. Using a crimping tool, connect ring terminal to the end of ground (green) wire.

Examine or check the motor. Using a flat head screwdriver remove four hex head screws securing cover plate of conduit box. This is located on the motor.

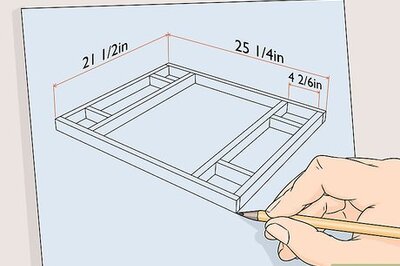

Prepare Motor. Using standard wire connectors twist and connect wires in the following order: Tip: When making the connections, trim the wires to a uniform length so they will “dress” into the box neatly. This prevents cramming the wires and making a mess. 9 to 3 8 to 2 7 to1 4 to 5 to 6

Connect motor to power source. Feed exposed end of power cord through circular hole of conduit box.

Wire power cord to motor. Connect power lines to wires located within motor by using standard wire connectors in the following order: 8,2, L2.jpg 9 to 3; L1 8 to 2 to L2.jpg 8 to 2; L2 7,1, L3.jpg 7 to 1; L3 20171220_184210.jpgThe ground (green) line is connected separately to a green ground screw located within the conduit box of the motor. (To do this remove screw completely, attach the ground wire to screw. Finally re-insert screw.)

Check all connections. Ensure all of connectors and wires are tight and secure. Tug on connectors lightly to confirm proper installation.

Check continuity of connections. Using a multi-meter/electrical tester check the continuity of all connections, to do this:

Switch multi-meter/ electrical tester to continuity function.

Place tip of red test lead into electrical connector and the tip of black test lead onto the any pin of the plug. Observe multi-meter/ electrical tester for any output of sound. If no sound is observed, place black test lead on a different pin, until sound is observed. Repeat this process for every connection in conduit box. If continuity does not exist on all four connections, PLEASE check connections to proper confirm installation.

Reattach cover plate. Using a flat head screwdriver insert and secure four hex head screws of cover plate to conduit box.

Plug in motor to ensure proper function. If the motor spins in the wrong direction, simply switch the location of two of the power lines, the will reverse the rotation of the motor.

Comments

0 comment