views

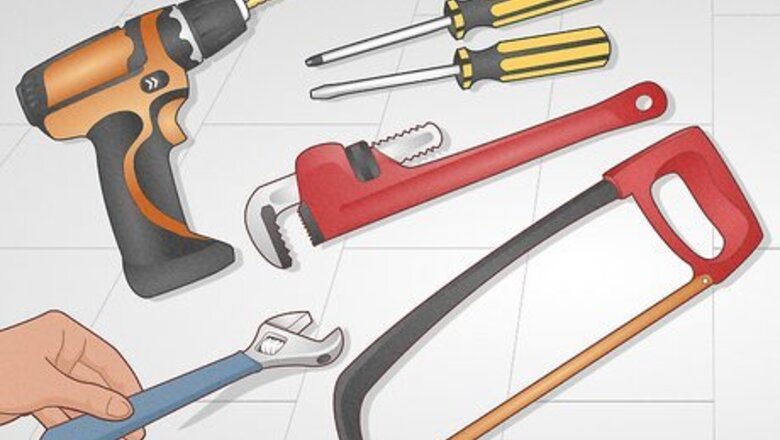

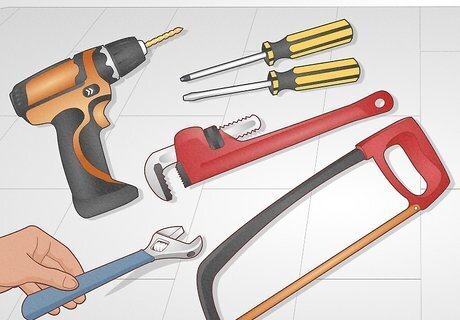

Gather your tools.

You need a pipe wrench, a drill with 3/32" and 1/4" bits, a screwdriver, a hacksaw, and an adjustable wrench.

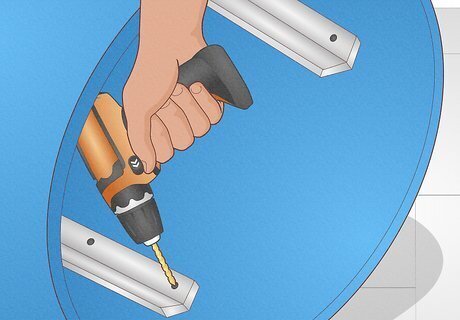

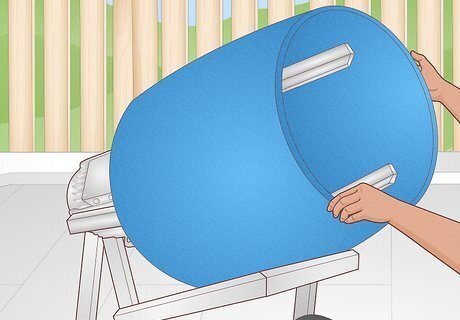

Make the three in-the-drum paddles.

Get brackets, corner supports, or angle-iron scrap that can be trimmed. If you can't find that, cut the blades from 18-gauge sheet metal. Bend the blades and drill 2 1/4" holes in each section. Dig identical holes in the tub and secure them with 1/4" bolts.

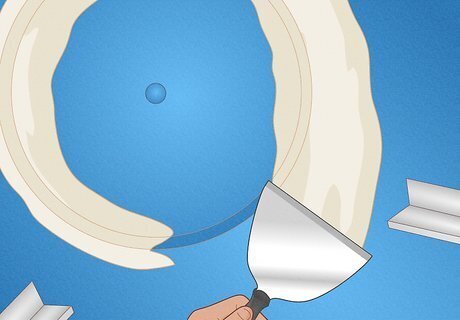

Apply bondo liberally to the bottom and sides.

Putting bondo on the vessel's interior seals its holes.

Thread the pieces together to form the frame.

Mount the smaller rollers by pushing a nail into the disks. Tee fit and fasten it with a nut. Then, attach the main wheels as well.

Mark and drill the cotter pin holes close to the disks.

Slip the axle shaft through its tubular housing to make sure the large hubs are secure. Then, put on the wheels and washers. Mark and drill the cotter pin holes as close as possible to the disks, to prevent the shaft from having excessive end play and wobble.

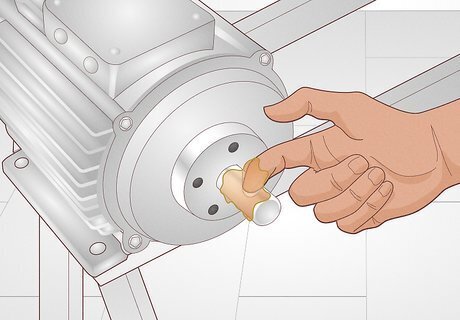

Grease the axle and secure the assembly with 2 cotter pins.

The mixing drum rotates on the shaft fastened to the central pipe cross. Grease the pipe to slip the conduit over that, and lubricate the assembly yet again.

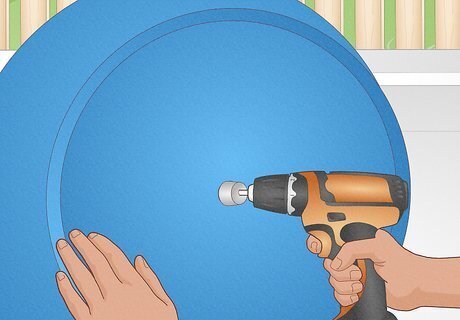

Slide the tub over the shaft.

Thread on the pipe cap to hold the components in place.

Attach handles and paint the assembly (if desired).

Handles and paint are totally optional. You can use a set of bicycle grips for the handles.

Comments

0 comment