views

Sealing the Structure

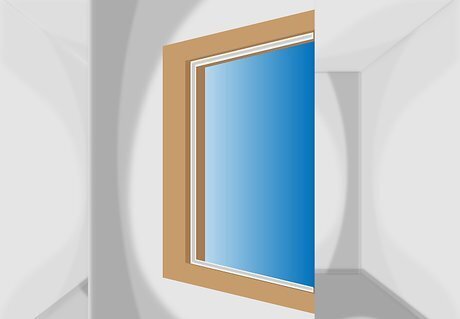

Replace broken windows. There is no use insulating the walls if the windows are gapped or broken.

Consider installing double glazed windows. If you are going to use it for a guest room or home office, this is essential, since single glazed windows will allow a large amount of heat loss, and depending on which side your shed faces, let a lot of heat in during summer.

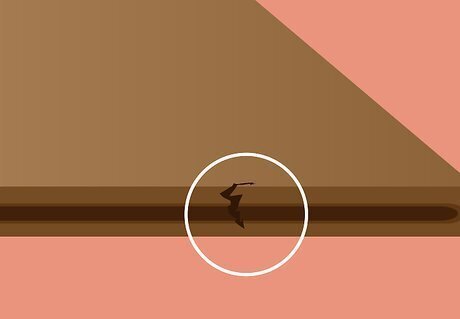

Patch gaps in the roof, siding, and around the foundation. Seal thin gaps with caulk. Use expandable spray foam for larger holes.

Examine the shed during rainfall, to see if any water is leaking in. Install a roof with a good drainage system. You can use shingles, metal roofing, or fiberglass. In the absence of rain, use a garden hose and spray it over the roof. Look inside for signs of leakage.

Consider siding the shed if there are a lot of gaps. Filling holes and establishing a barrier between the outside is important if you are going to keep the temperature constant inside the shed. Look for dark stains in the walls to identify water leaks in the shed.

Buy a weatherproof door. Most shed kits don’t come with a weatherproof model. You may need to purchase a custom size if your shed door is smaller than a standard home door.

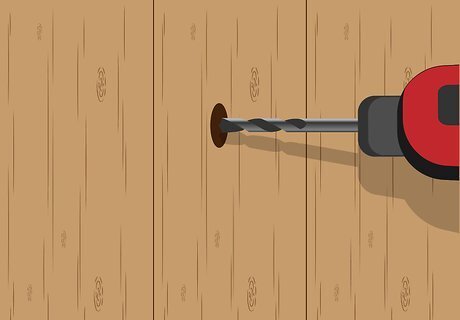

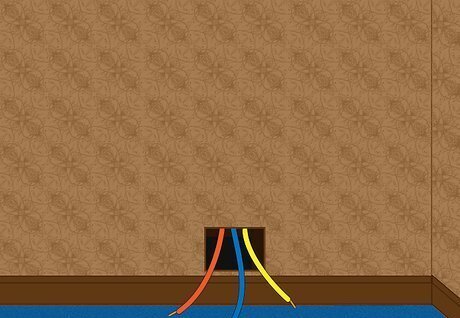

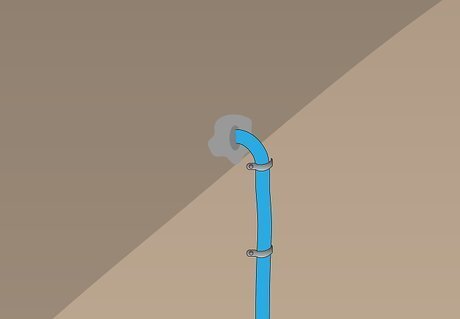

Get the shed fitted with electrical wiring if you want to install a heating system or lights. Hire an electrician to ensure it will be safe. Extension cords from the house are not safe.

Choosing Insulation

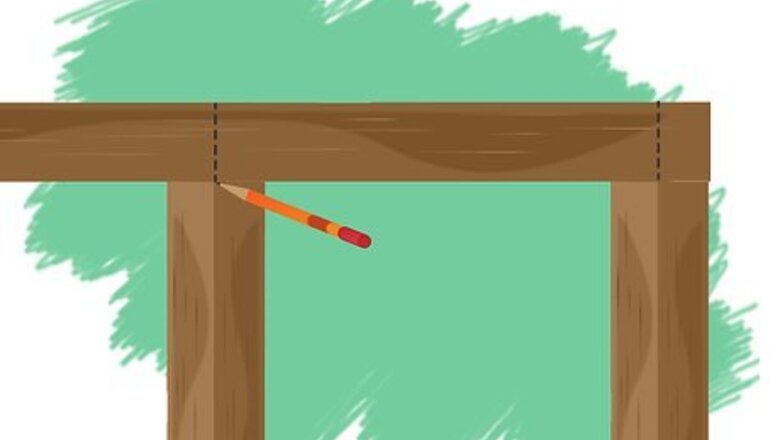

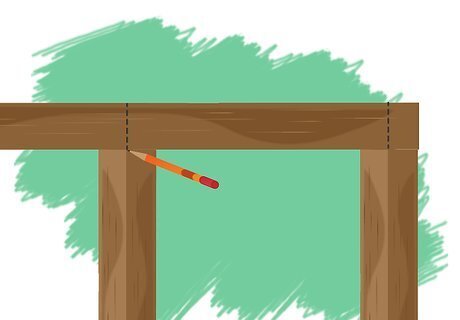

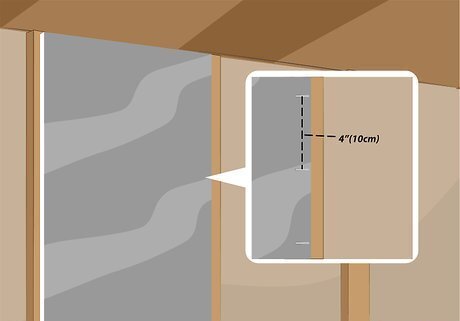

Measure the space between the studs. This space will dictate the width of the sheets or batting you are going to buy.

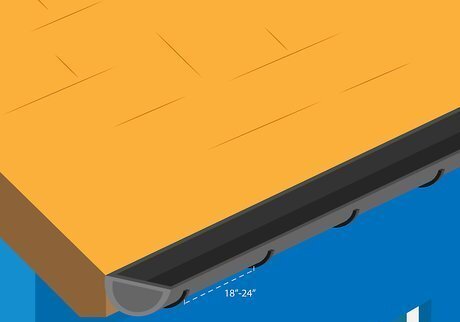

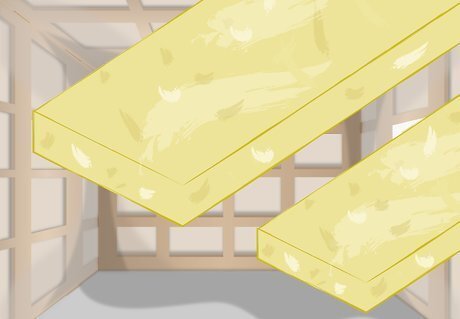

Pick blanket or batt insulation if your studs are 18 to 24 inches (45.7 to 61.0 cm) apart. These standard wall sizes allow you to roll out and secure the insulation between studs, joists, and beams. It is relatively expensive and best on unfinished walls.

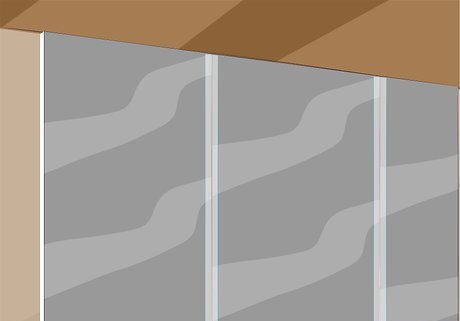

Move to foam board or polystyrene sheets if the studs are not a standard length but they are at regular intervals. They are fairly thin but work well, although they are not recommended if you have a lot of electrical outlets.

Choose wool insulation if you need an insulation that can withstand high temperatures. Keep in mind that wool will need regular upkeep and maintenance. Without proper cleaning, wool will break down and rot over time from its natural dirt and oils. Although fiberglass insulation is a similar option, it must be covered or it is unsafe for humans.

Choose foam, loose fill, or spray insulation if the shed walls are already finished with drywall. You can cut holes into the walls and blow the insulation into the frame.

Select reflective foil-faced insulation if you want a do-it-yourself insulation on a standard frame. It is flexible, so that it can bend around corners or other obstructions.

Installing Insulation

Hire a professional contractor if you choose blown-in in or foam insulation. Some of these methods require special equipment.

Take your shed measurements into the home improvement store. They should help you to purchase enough to cover the shed. They will require your stud spacing measurements as well.

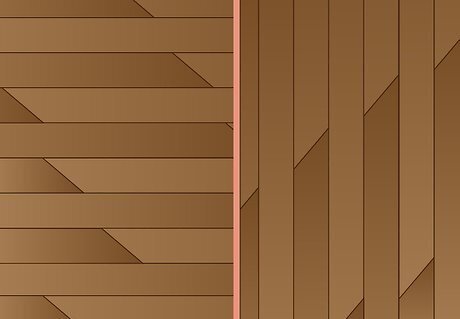

Roll the sheets of batting or foil out horizontally. Set the polystyrene against the frame.

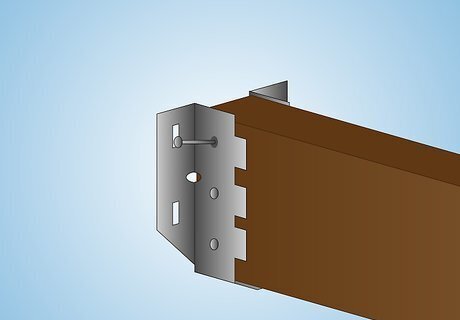

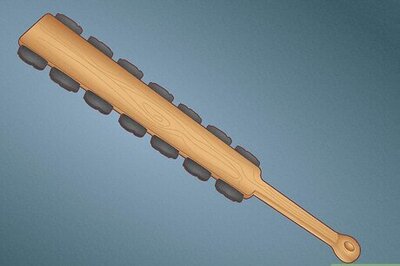

Attach batting or with a staple gun if you are using foil sheets or batting. Staple it into the studs. You will need to glue polystyrene sheets onto the walls and studs with a special adhesive.

Overlap sheets of insulation where they meet. Continue moving up the wall in horizontal sheets. You can cut the insulation sheets with scissors to make a smaller section.

Insulate the ceiling as well as the walls. You will need to leave at least a two-inch gap between the top of the ceiling and the insulation to let moisture escape.

Cover the insulation sheets with sheets of drywall if you want the shed interior to be attractive. You will want to hang the sheets on the ceiling first, followed by wall sheets.

Comments

0 comment