views

X

Research source

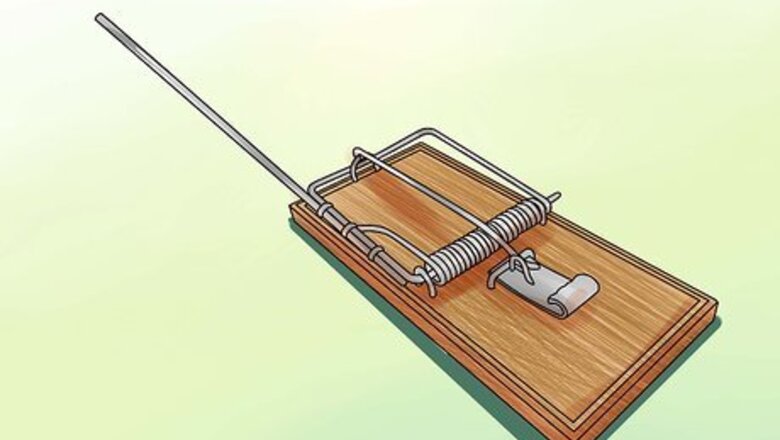

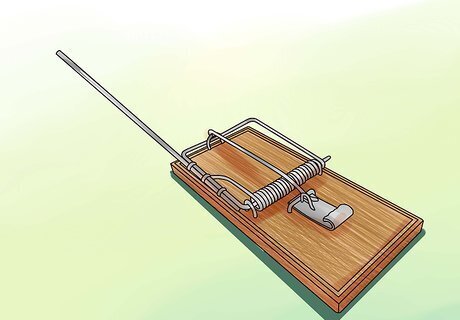

Increasing Acceleration

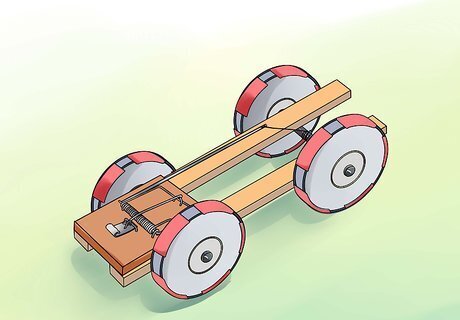

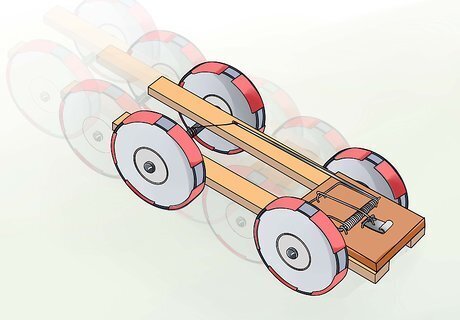

Shorten the lever arm. Installing a shorter lever arm is the best way to adapt a racer for speed. However, if the lever is too short, it will spin out. There is no precise formula for how long the lever should be. Experiment to see how short you can get the lever while maintaining control of the car. Longer lever arms will extend the time in which the axle is pulled, making it travel longer distances before the car reaches maximum speed. As a result, it will go slower but move further.

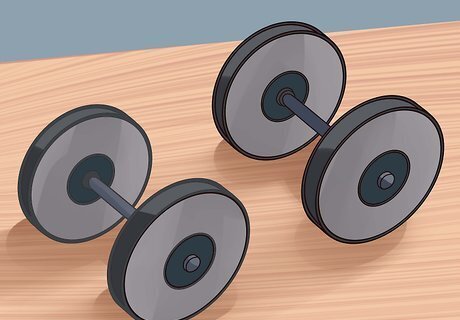

Find smaller wheels. When you increase the size of the wheel, the amount of torque necessary to begin a rotation increases as well. A smaller wheel is easier to turn. So you should make sure that your driving (front) wheel is as small as possible. A good standard is approximately 3 inches (7.6 cm) in diameter. Use materials that are as lightweight as possible. A larger wheel means more rotational inertia, which keeps the wheel moving once it gets going, but reduces acceleration. A smaller wheel is a trade-off between distance and speed. The overall distance traveled will decrease as you reduce the size of the driving wheel. Experiment to determine what the most functional design is.

Increase the size of the axle. The greater the ratio of the diameter of the axle to the wheel, the less force will be required to accelerate the car. In other words, you should match a larger axle with a smaller wheel to increase acceleration. Conversely, a mousetrap racer built for the distance should have a smaller axle and a larger driving wheel. One way to adapt the size of the axle is to wrap the tape around the center of the axle, where it does not come into contact with the frame. This added weight will increase the torque of the axle. Experiment to find the correct amount of torque by adding and removing layers of tape.

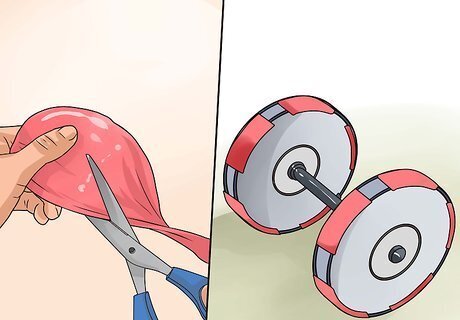

Increase traction. For the wheel to pick up speed it needs to create pressure against the ground. For the wheel, use a material with a rough texture around the outside to give the wheel traction. Alternatively, cut something that has a rough surface such as a rubber balloon. Glue strips of this material to the outside of the wheel to give it traction.

Keep on trying. There are so many variables involved in the physics of a mousetrap racer that even similarly built cars operate differently. The only way to perfect your model is to experiment with small variations in design to determine what works best. Study mousetrap racers that have won competitions in the past. Learn from designs that you know work.

Reducing Resistance

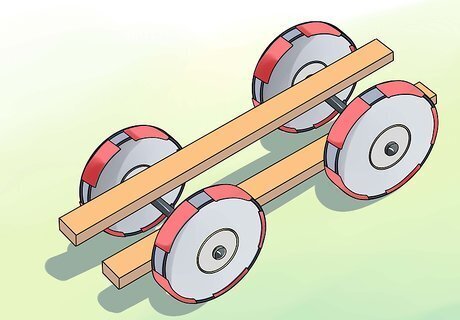

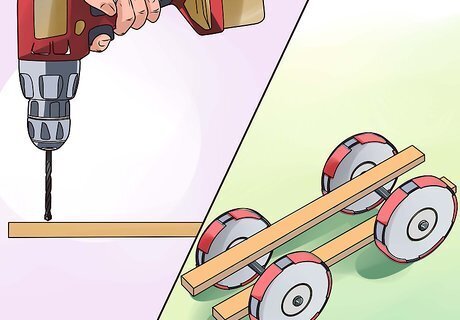

Reduce weight. Reducing the weight will lower rolling friction with the ground. Trim the deck down so it is only as large as necessary to support the mousetrap. When gluing down the deck, put it as close to the back wheels as possible without touching them. Drill holes in nonessential components to reduce weight. Consider drilling holes in the frame and the wheels as well. The material used for the frame of the car should be as lightweight and as rigid as possible. Consider bamboo, balsa wood, or foam. Use glue whenever you need to attach something. Tape can be used too, but glue is smoother and weighs less. Don't use metal bolts, however; they add weight.

Cut down on the number of pulleys and gears. A complicated system of gears and pulleys can be useful when building a racer for distance because they increase the overall torque. However, when building for speed, they principally serve to create more friction between the components. Consider connecting the lever directly to the axle when building a car for speed.

Limit air resistance. As speed increases, so too does air resistance, making it progressively more likely to stop your car in its tracks. To prevent this from happening, make sure that as little surface area as possible is exposed. Experiment with different materials for frames to see what is most aerodynamic. If you are using a wood frame, sand it and paint it. This will make it more aerodynamic. Similarly, reduce the surface area of the car to reduce air resistance. For example, find a thinner frame and wheels.

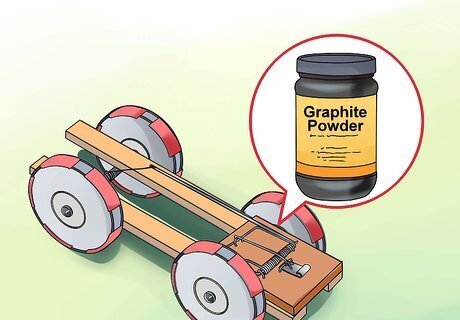

Eliminate friction between the axle and the frame. Your car can lose a lot of energy at the point where the axle touches the frame. Watch these surfaces to see if the axle seems to get stuck. Try applying a lubricate, like graphite powder. Alternatively, redesign the axle. Consider installing ball bearings. You can search online for a chart of coefficients of friction, to determine which materials have the least friction when paired.

Comments

0 comment