views

Removing the Tire

Park the vehicle on level ground and engage the parking brake. Find a nice, even spot to park your vehicle such as a driveway or garage. If the vehicle is a standard or manual transmission, pull the parking brake to engage it. If it’s an automatic transmission, locate the parking brake near the driver-side door and step on or push it to engage it. Working on an angled surface will make it difficult for you to access the suspension spring.Warning: If your vehicle moves while you’re replacing the suspension spring, it could potentially fall off the jack or the spring could shoot out and cause serious injury.

Loosen the lug nuts on the tire you plan to remove with a tire iron. Take a standard tire iron and connect it to 1 of the lug nuts on the tire. Turn it just enough to loosen the lug nut, but don’t remove it. Loosen all of the lug nuts on the tire. If your vehicle has a hubcap that’s covering the lug nuts, you’ll need to remove it by prying the corner with a flathead screwdriver. It’s much easier to loosen the lug nuts before you jack up the vehicle.

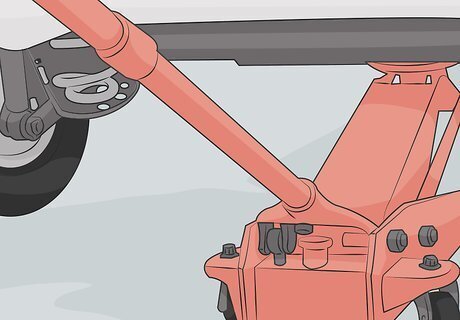

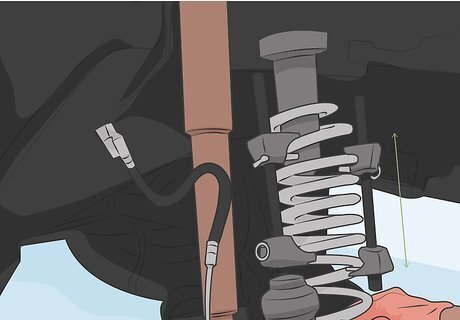

Slide a jack beneath the axle near the tire and raise it up. Use a standard vehicle jack and locate the vehicle’s axle on the underside, near the tire you plan to remove. Slide the jack beneath the vehicle and place the top of it against the axle. Crank or turn the jack to raise it until the bottom of the tire is suspended about 2–3 inches (5.1–7.6 cm) in the air. The vehicle only needs to be jacked up enough to make it possible to remove the tire.

Remove the lug nuts and slide the tire off of the vehicle. With your hands or using the tire iron, unscrew all of the lug nuts from the tire. Then, use both of your hands to grip the outside of the tire and pull it off of the vehicle. Set the tire and lug nuts off to the side. Most vehicles have tires with between 5 and 6 lug nuts.

Detaching the Old Spring

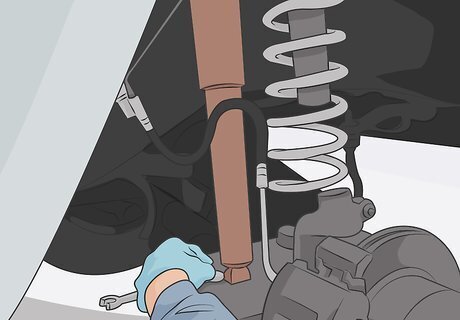

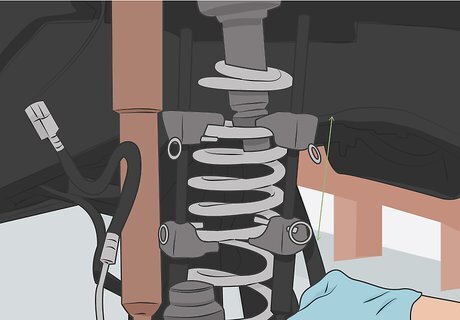

Use a socket wrench to unscrew the bolt attaching the shocks to the spring. The shocks of your vehicle look like a metal shaft with a tube wrapped around it and they’re connected to the metal struts that also hold the suspension spring. Take a socket wrench and remove the bolt at the connection point between the shocks and the struts. Then, use your hands to move the shocks off to the side so they’re out of the way. If you’re having trouble finding the shocks, look for the suspension spring coiled around the strut, then look for the shaft that’s connected to the strut.

Unscrew the bolt connecting the sway bar to the spring with a socket wrench. The sway bar is a metal rod that’s connected to your vehicle’s struts and helps to stabilize it whenever you take sharp turns. Locate the sway bar and find where it’s connected to your vehicle’s struts. Use a socket wrench to remove the bolt connecting them together and then use your hands to move the sway bar out of the way. You may need to pull the sway bar off of the struts once you remove the bolt.

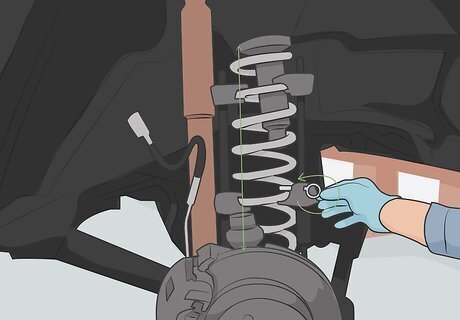

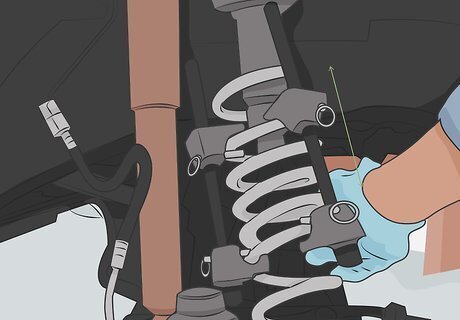

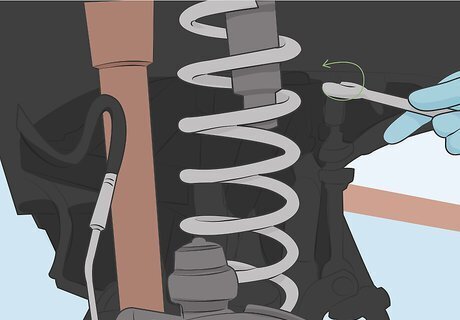

Attach 2 spring compressors to the outside of the suspension spring. Spring compressors look like thin clamps with hooks on each in that keep your spring compressed so you can safely remove it. Hook a spring compressor over the top and bottom of the spring. Then, hook another spring compressor directly across from it. You need to use 2 spring compressors in order to safely keep the spring under tension. You can find spring compressors at auto supply shops and online.

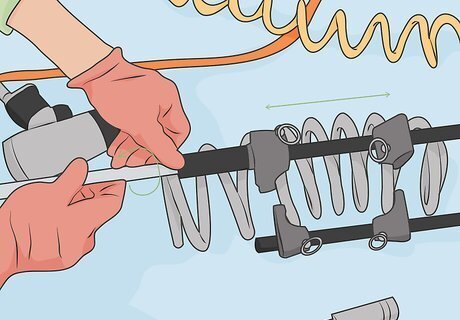

Tighten the compressors with a wrench or drill until the spring separates. Fit a socket wrench, impact wrench, or a drill with a socket attachment over the screw end of the compressor and rotate it to tighten it. Alternate back and forth between both compressors and tighten them a little at a time so they compress the spring evenly. Continue compressing the spring until it separates from the strut. Make sure the spring is evenly compressed after it separates.

Pull the compressed spring off of the vehicle. Remove the wrench or drill from the compressor and take a firm grip on the spring with your hands. Pull the spring off of the vehicle and place it on the ground. You may need to push down on the control arm beneath the spring in order to pull it off of the vehicle.

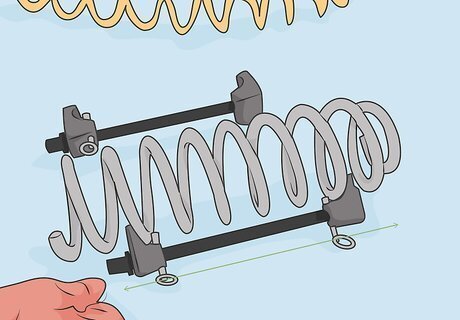

Loosen the compressors to remove them from the spring. Use your wrench or drill to slowly loosen the compressors a little bit at a time, alternating back and forth between them so the spring is decompressed evenly. Once the compressors are loose enough, remove them from the spring.Warning: If you loosen 1 compressor too quickly, it can cause the spring to shoot out and could cause serious injury. It’s extremely important that you slowly and evenly decompress the spring.

Installing the New Spring

Attach the spring compressors to the new spring and tighten them. Place the new spring on the ground and hook each of the compressors over the top and bottom of the spring, directly across from each other. Use a wrench or drill to tighten the compressors a little bit at a time, alternating back and forth between them so the tension is applied evenly to the spring. Continue compressing the spring until it can fit into the slot on the vehicle. Hold the compressed spring up to the slot where you need to fit it to see if it’s compressed enough.

Slide the compressed spring onto the vehicle until it clicks into place. Remove the wrench or drill and fit the compressed spring into the slot you removed the old one from on the vehicle. Slide the spring into place and turn it until it fits neatly and clicks into place. It’s very important that the spring is fit into place correctly in order for it to support the weight of the vehicle.

Reattach the sway bar and shocks and replace the bolts to secure them. Connect the sway bar back to the struts of the vehicle and tighten the bolt with a socket wrench so it’s secure. Then, reconnect the shocks to the struts by reinstalling the screw that you removed with a socket wrench until it’s tight. All of the attachments around the spring need to be tight and secure so the spring doesn’t fly off when you remove the tension.

Remove the spring compressors with a wrench or drill. Take your wrench or drill and slowly loosen the 2 spring compressors by alternating back and forth between them, easing a small amount of tension at a time so the spring is decompressed evenly. When they’re loose enough, use your hands to remove the spring compressors. The spring should be firmly held in place.Tip: Use your hands to shake the shocks, sway bar, and struts to make sure there isn’t any movement. If there is, use your socket wrench to tighten the connections.

Put the tire back on the vehicle and tighten the lug nuts. Slide the tire back onto the vehicle and use your hands to screw on the lug nuts as far as you can. When you can’t turn the lug nuts any further by hand, use your tire iron to tighten 1 lug nut as much as you can, then tighten the lug nut across from it. Continue tightening the lug nuts in a star-shaped pattern so the tire is attached evenly.

Lower the vehicle and remove the jack. Rotate the rod in the opposite direction to lower the vehicle the ground. Lower the jack all the way so the tire is on the ground and you can slide the jack out from underneath the vehicle.

Comments

0 comment