views

Accessing the Ferrule

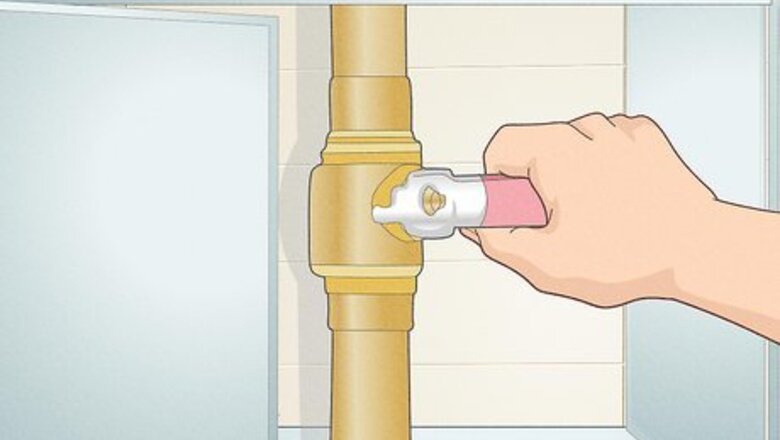

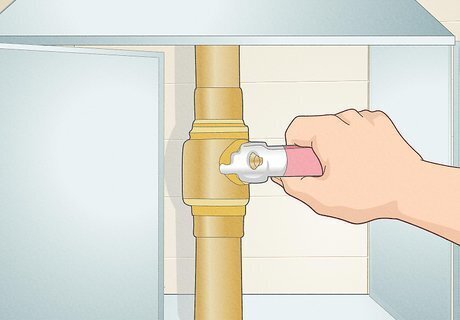

Turn off your water supply. Since you’re removing the valve from the pipe, water will spray out from the pipe if you leave the supply on. You’ll typically find your main water supply valve in a basement, garage, or utility room, but it may be along an exterior wall as well. Tighten the valve by turning it counter-clockwise so the water shuts off. You’ll need to change a ferrule if you’re replacing a compression-fit connection on a water valve, which will usually attach to a sink or toilet. These methods will work whether your pipe is copper, plastic, or brass. Other fixtures won’t work while you have the water off, so let other people in your home know when you plan on making your repairs. Never work on your plumbing with your water supply on since it could leak and cause water damage in your home.

Drain the water line in the area where you’re working. Turn on the faucet or use the fixture that’s connected to the pipe you need to access. Let the water flow until you don’t see anything coming out from the faucet anymore. If you’re working on a toilet valve, keep flushing the toilet until there isn’t any water in the tank.

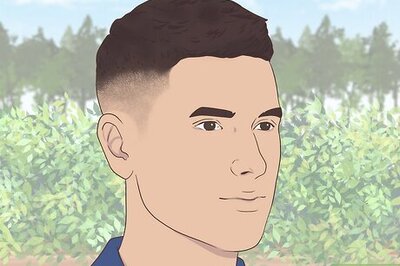

Unscrew the angle stop from the pipe. The angle stop is the valve control found underneath or near the fixture you’re working on. Grip the nut closest to the wall or floor with a pair of pliers. Hold onto the front of the angle stop so it stays in place. Turn the nut clockwise to loosen it from the angle stop. Then you can turn the nut by hand until it detaches from the angle stop to reveal the ferrule wrapped around your pipe. If you have trouble holding onto the front of the angle stop, grip it with another pair of pliers so it doesn’t turn. There might still be a little bit of water left in the pipe. Place a towel or bowl underneath the valve so you don’t spill too much.

Pushing a Ferrule off with Pliers

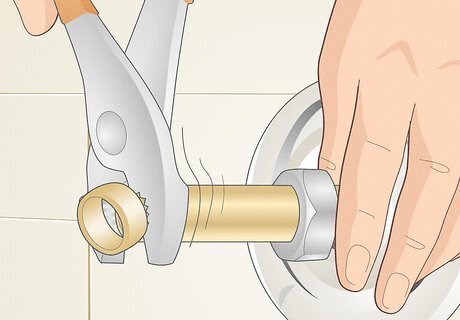

Try twisting the ferrule with pliers first to see if you can shimmy it off. Open the jaws on a pair of pliers so they fit around the ferrule on your pipe. Tighten the pliers again so they grip onto the ferrule firmly. Hold onto the pipe with your nondominant hand for some additional support. Move the pliers’ handles up and down as you pull the ring toward the end of the pipe. If the ferrule isn’t too tight, then you’ll shift it down the length of the pipe until it falls off. If you can’t move the ferrule using this method, then move on to the next step.

Tighten pliers around the pipe behind the ferrule if you couldn’t twist it off. Open the jaws on a pair of pliers so they’re slightly wider than the pipe’s diameter. Place your pliers behind the ferrule so the pipe is between the jaws. Close the pliers so they loosely fit around the pipe so that you can easily move them back and forth along the length. Be careful not to tighten the pliers so much that you aren’t able to move them. If there’s a compression nut behind the ferrule, slide it up against the ferrule before securing your pliers around the pipe.

Slide the pliers forcefully into the back of the ferrule. Hold the base of the pipe with your nondominant hand so it doesn’t move around or get damaged. Move the pliers as far back along the pipe as you can. Then, forcefully slide it forward to hit the ferrule. You should notice the ferrule shift slightly down the length of the pipe. If you don’t see the ferrule move, try hitting it again. This works best if you have a longer length of exposed pipe so you can have enough power to hit the ferrule.

Keep hitting the ferrule until it falls off of the pipe. Continue striking the ferrule with your pliers to move it down the length of the pipe. When you almost have the ferrule off, cup your hand around the end of the pipe. Hit the ferrule a few more times and catch it when it comes off of the end. If your ferrule doesn’t budge at all, then you might not be able to force it off using only pliers.

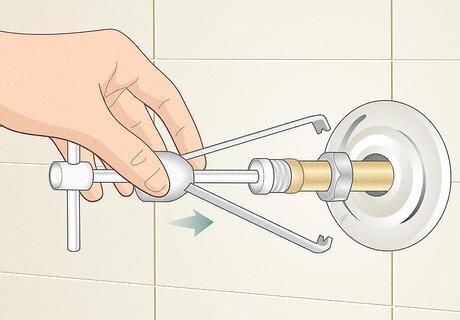

Using a Compression Ring Puller

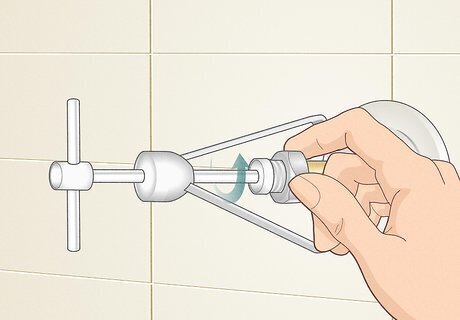

Slide a compression ring puller into the pipe. Compression ring pullers apply pressure to the back of the ferrule to help move it down the pipe. Line up the puller’s center column with the pipe and push it in as far as you can. Keep the 2 arms on the sides perpendicular to the pipe for now so they’re out of your way. You can buy a compression ring puller from the plumbing section at a hardware store. Some compression ring pullers have a separate guide that goes inside the pipe instead. After you insert the guide, screw the center column of the puller into the guide.

Screw the compression nut onto the puller. The central column of the compression puller has a threaded end that holds the nut tightly against the ferrule. Hold the compression nut against the threading and turn it counterclockwise by hand. Keep screwing the nut onto the puller as far as it will go until it’s hand-tight. If your compression puller had a guide that inserted into the pipe, then you might not need to screw in the nut. Check the manual for the puller you’re using.

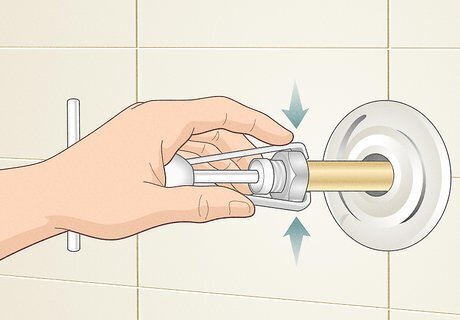

Hold the puller’s arms against the back of the nut. Bend the arms toward the pipe so they wrap around the backside of the nut. Squeeze the arms tightly around the pipe and hold them in place with your nondominant hand. That way, the arms will apply pressure to push the nut and ferrule off of the pipe. You can also keep the arms pressed against the back of the ferrule if your pipe doesn’t have a nut on it. You may be able to lock the arms in place so you don’t have to hold them manually. Check the instruction manual that came with the puller to ensure you’re using it properly.

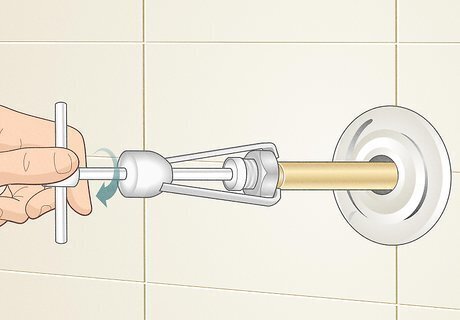

Turn the puller’s handle clockwise to remove the ring. Hold the arms in place with your nondominant hand and operate the handle with your dominant hand. Keep spinning the handle clockwise so the nut and ferrule slide toward the end of the pipe. When they reach the end, the ferrule and nut will fall off. If the ferrule still won’t move, then you’ll have to cut it off.

Cutting a Stuck Ferrule with a Saw

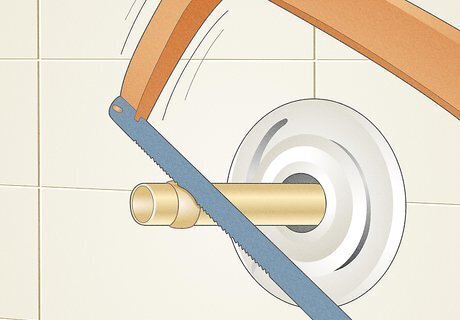

Cut a slot in the ferrule with a hacksaw. Position a hacksaw on top of the ferrule so the blade makes a 45-degree angle with the ferrule’s side. Apply light pressure and work the saw back and forth to cut into the ferrule. Work slowly and carefully so the blade doesn’t jump, and saw completely through the ferrule. You can also use an angle grinder to cut through the ferrule. Stop sawing the ferrule occasionally to check that you haven’t cut into the pipe, or else it’s more prone to leaks later on.

Twist a flathead screwdriver in the slot to loosen the ferrule. Put the tip of a flathead screwdriver into the cut and push it against the pipe. Turn your screwdriver by about half a turn in either direction so the ferrule separates. After that, remove the screwdriver.

Slide the ferrule off of the pipe. Grab the ferrule, being careful of the sharp cut edges, and slowly pull it toward the end of the pipe. Since you cut the ferrule and separated it, it won’t be as tight on the pipe so you can remove it by hand.

Comments

0 comment