views

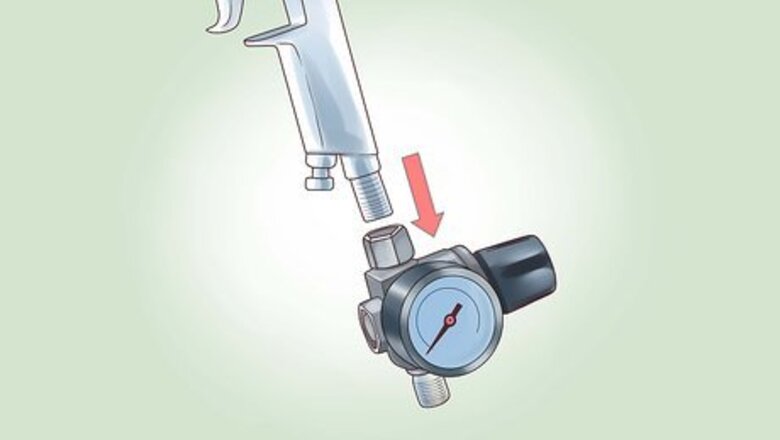

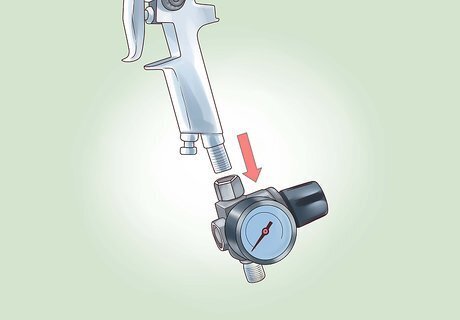

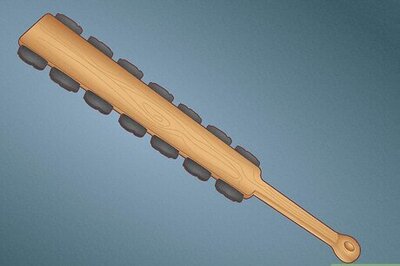

Remove the air regulator from the paint. The air regulator is the device at the bottom of the gun where compressed air can be hooked up to the bottom of the air gun. Make sure that the compressed air source is disconnected from the regulator first and then you can disconnect the regulator from the gun.

Open the lid from the paint cup to pour out any unused material. You need to make sure you dispose of the waste in the proper containers. There should be at least two containers for the unused material: Hardened (Catalyzed) Material. This means any materials that do not stay a liquid form but turn into a solid material. Base coat (Liquid) Material. This means the any material that stays in liquid form.

Using paper towels, wipe as much left over material from the cup and lid of the cup as possible. By wiping out the excess material will make cleaning out the cup and lid a lot easier with the thinner. Bear in mind that when drying with paper towels paint thinner is a corrosive liquid and easily able to deteriorate and soften the towels being used.

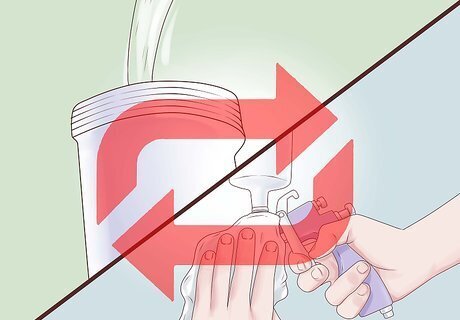

Pour a small amount (fill gun throat to overflowing) of waste thinner into the cup. Waste thinner is also referred to as recycled thinner; it is paint thinner that has been used before. The throat of the gun is in the inside at the very bottom of the cup.

Shake the paint gun vigorously ensuring to coat the inside of the cup with thinner. To elaborate this is to make sure that all the remaining paint or base coat is dissolved by the thinner.

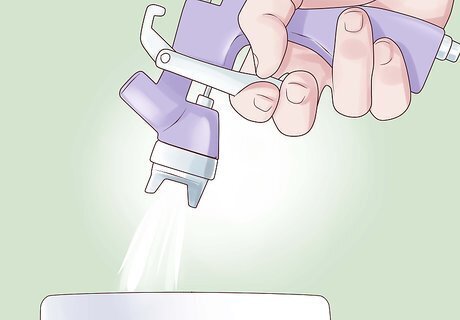

Run used thinner into waste thinner container through the fluid nozzle. To do this you point the nozzle into the container and squeeze the trigger like you would in normal operation.

Wipe down all parts with paper towels until dry.

Repeat steps four through seven at least once or until satisfied with initial cleaning.

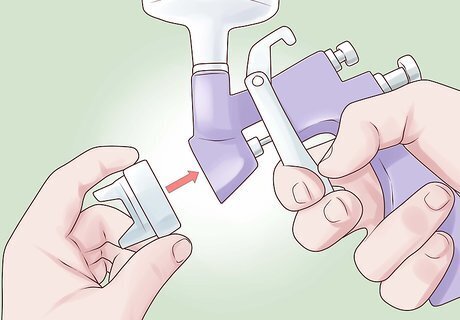

Remove the paint cup by turning it counter clock wise until it comes off. Remove the paint cup lid as well.

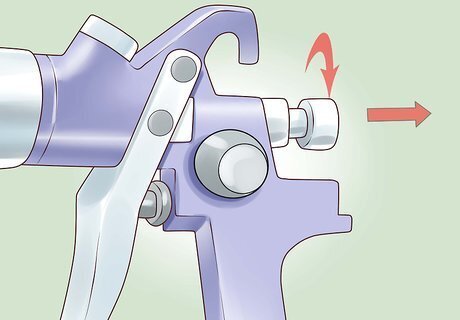

Remove the fluid needle to avoid bending or damaging the needle during the removal of other parts. To do this, first remove the fluid adjustment knob, located on the rear of the gun, it is generally the middle knob although this can vary depending on model. Clean all parts with waste thinner as you remove them.

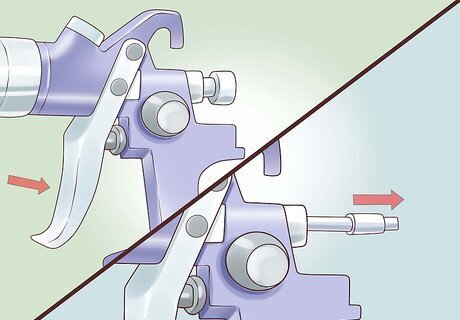

Take the now revealed spring out, press on the trigger, and pull the fluid needle straight out. Again, clean all parts with waste thinner as you remove them.

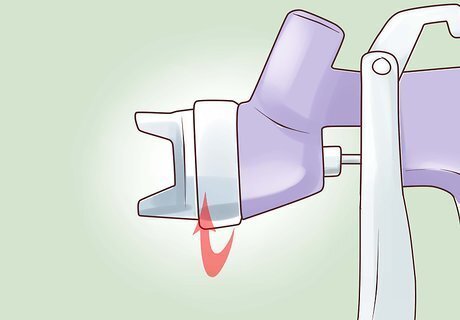

Remove the air cap on the front of the paint gun by turning it counter clock wise until it comes off. Then using the paint gun key find the correct size for the fluid nozzle and remove the fluid nozzle by turning counterclockwise. To reiterate, clean all parts with waste thinner as you remove them.

When satisfied with secondary cleaning wipe dry and begin rinse with clean thinner. Rinse gun body, cup lid, air cap and all parts that have remaining paint, excluding any gaskets. Though this process can be quite repetitive, doing so well only save you from future headaches and you can be assured a clean paint gun.

Dry all parts with clean paper towels and if available compressed air. Use the compressed air to clean holes and moving parts that can’t be reached with just wiping. Last make sure gun is completely dry after using compressed air, as excess liquids can be blown back onto the surfaces from the pressure on crevices and moving parts.

Reassemble the gun and parts. Lubricate moving parts and threads as you replace them. You want these parts to be oiled to prevent sticking or seizing of removable and non-removable mechanical moving parts.

Wipe any excess oil off the gun with clean paper towels. After you have finished the gun is ready for use or storage.

After all steps have been completed begin final clean up. Start by making sure all waste material is contained in appropriate containers away from any heat source. Next, make sure all work stations and tools are clean and put away. After completion of this step you have a clean, contaminant free paint gun and work station.

Comments

0 comment