views

Removing Oil and Grease

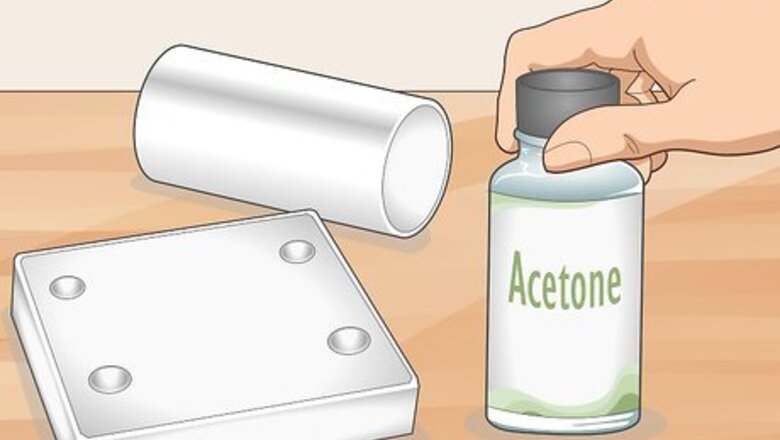

Use acetone or lacquer thinner to degrease aluminum. Acetone and lacquer thinner are natural solvents that are safe for aluminum and work well to remove oil and grease from surfaces. Methyl ethyl ketone and toluene are 2 alternative solvents that you can use. Don’t use alcohol to degrease aluminum because it is not an effective degreaser.Warning: Always start cleaning aluminum by degreasing it. Don’t try to clean it right away with something abrasive like a wire brush, or you will just spread the oil and grease around and create small scratches on the surface that contain contaminants. Contaminants like oil and grease contain hydrogen, which can cause weld porosity if they come into contact with your welding arc. You could also use a commercial degreaser that is made for aluminum, as an alternative to a solvent. If you do so, choose one that is biodegradable and environmentally friendly.

Open up doors and windows to ventilate your workspace. Create as much ventilation as possible, so you aren’t breathing in excessive fumes from the solvents. Breathing in large amounts of solvent fumes can cause lung, throat, and nose irritation. If you can’t open up any doors or windows to get some airflow in your workspace, take the aluminum somewhere outside to degrease it. If you ever feel dizzy when you’re working with solvents, stop immediately and leave the area to avoid breathing in more fumes.

Put on gloves and protective eyewear. Wear work gloves, rubber gloves, or latex gloves to protect your skin from the solvent. Use safety glasses or goggles to protect your eyes. Some solvents can cause skin and eye irritation, so always take the proper safety precautions before working with solvents. If you ever get a solvent splashed in your eyes, stop working immediately and go flush your eyes out under cool running water.

Dip a clean, lint-free rag into your chosen solvent. Pour some of the solvent out into a container. Hold the cloth and submerge it in the solvent to saturate it. A microfiber cloth works best for this. You could also cut up an old, clean T-shirt to make some lint-free rags.

Wipe down all the parts you plan to weld with the solvent-soaked rag. Rub the rag in circular motions all over every surface of each part that you are going to weld. Re-wet the rag as you go if the parts are large and you need more solvent. It’s important to be very thorough and wipe down all the surfaces of each piece of aluminum, rather than just around the area where you are going to weld. Oils and grease can get spread around very easily, so make sure the aluminum is completely degreased.

Wait 5-10 minutes for the solvent to evaporate before you proceed. Leave the aluminum pieces to dry for 5-10 minutes before you continue to clean the aluminum. Solvents evaporate on their own very quickly, so you don’t need to worry about drying the pieces by hand. Never weld any parts right after degreasing them. If solvents come into contact with your welding arc, they can release poisonous gases.

Getting Rid of Surface Oxides

Use a stainless steel brush with soft, fine bristles to clean the aluminum. A manual or power brush will work for removing surface oxides. Don’t use brushes with large, stiff bristles, as these will burnish the oxides instead of removing them. Make sure that the brush is clean, so you don’t transfer any contaminants to the aluminum. Surface oxides are a form of corrosion that metals form due to contact with the air and moisture in the air. Visible rust occurs on metals when there are high levels of oxidation, but oxide layers start to form whenever metal sits out in the air. This means that your aluminum pieces can have surface oxides even if it doesn’t look like it.

Apply white vinegar to the aluminum using a clean, lint-free cloth. Vinegar is a weak acid that works to deoxidize aluminum. Soak a clean, lint-free cloth, such as a microfiber cloth, in white vinegar and rub it all over every surface of the aluminum parts you plan to weld.Tip: You can use a commercial oxide remover as an alternative to vinegar. These commercial solutions contain a blend of detergents and acids for removing oxides and come in a spray bottle or jug. You could also put the vinegar into a spray bottle and spray it directly onto the aluminum, rather than wiping it on.

Scrub all surfaces of the aluminum pieces gently with your wire brush. Press the brush lightly against the aluminum. Rub it in circular motions, applying gentle pressure the whole time, all over the aluminum pieces you plan to weld to rub the vinegar in and scrub off surface oxides. Applying too much pressure can burnish surface oxides and actually drive them further into the aluminum surfaces, so always scrub gently.

Rinse and dry the aluminum. Rinse the aluminum piece under running water or spray it down with a hose, depending on how big it is, to clean off the vinegar. Dry it off thoroughly with a clean, lint-free cloth.

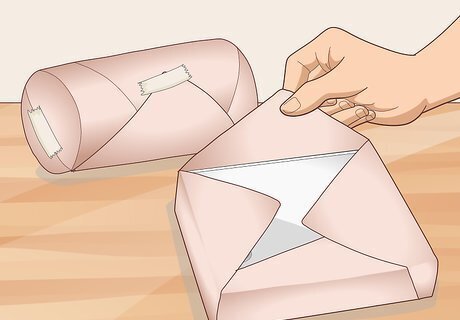

Wrap the aluminum in kraft paper and tape it up if you won’t weld it right away. Cover each aluminum piece in kraft paper to protect against dirt and grime. Tape the paper up using packing tape or masking tape to seal the aluminum inside. As long as you protect the aluminum this way, you can weld it any time in the next 3-4 days or so. If you leave it longer than that, clean it again before you weld it to remove surface oxides.

Comments

0 comment