views

Planning Your Wind Turbine

Determine the average wind speed where you plan to build. To cost-effectively generate electricity, an efficient wind turbine needs wind to reach at least 7 to 10 miles per hour (11 to 16 kilometers per hour). Most wind turbines perform best at speeds from 12 to 20 mph (19 to 32 kph). To find the annual average wind speed for your area, you can check online wind maps that list the average wind speed in your area. You can also purchase a wind measuring tool, called an anemometer, and use it take the wind speed at the location of your planned turbine. Do this daily for a period of time. If the wind speed in your area is fairly consistent, a month of readings should be more than enough, though seasonal changes can drastically affect wind speed. Then, average your readings to see if a turbine at your location is reasonable.

Learn building code related to wind turbines. Building code changes from area to area, so you'll have to inquire with your local government to make sure your turbine you don't violate code. Some codes stipulate a minimum distance between turbines, as well as how far away the turbine has to be from the property line. There may also be height limitations imposed by local ordinances that you'll need to take into account when building. It's also a good idea to discuss building a wind turbine with your neighbors before investing too much time in planning and construction. This way, you can address their concerns about wind turbines and resolve any misconceptions they may have about noise, radio interference, and TV reception.

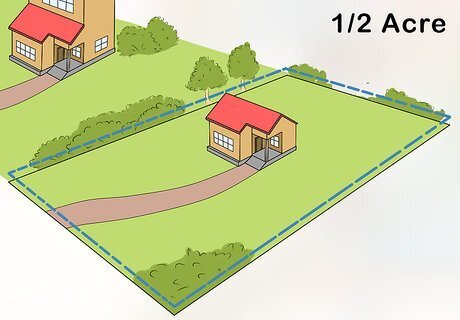

Evaluate spacing for your wind turbine. Although the turbine itself doesn't require much space, to avoid potential conflicts with neighbors, you should generally have at least half an acre (0.2 hectare) of space for a turbine that generates up to 3 kilowatts of power and a full acre (0.4 hectare) for a turbine that generates up to 10 kilowatts. You should also have enough vertical space to build the turbine high enough so that buildings and trees don't block the wind.

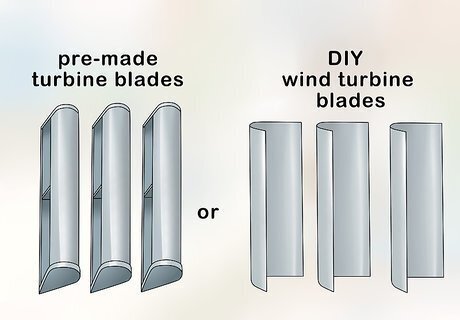

Choose between pre-made or DIY wind turbine blades. The kind of blades you use and configuration of your blades may affect the design of your turbine. Old farm windmills were basically small sails attached to a rotating shaft, but wind turbines resemble giant propellers and have large teardrop-shaped blades. These blades should be sized and pitched correctly for the turbine to work efficiently. If you choose to build the blades, you can make them out of wood or cross-sections of PVC pipe. Instructions can be found online through a general Internet search for "DIY wind turbine blades." Whether you build or buy the blades, you'll likely want to have 3 blades on your wind turbine. Using an even number of blades, such as 2 or 4, makes a wind turbine more likely to vibrate as it spins. Adding more blades increases torque but can make the turbine rotate more slowly. Blades can also be made from household products, like modified shovels. If you plan on going this route, choose a sturdy shovel, and you may want to replace wooden handles with something more durable, like a metal haft.

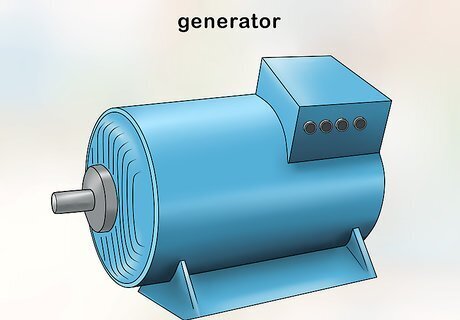

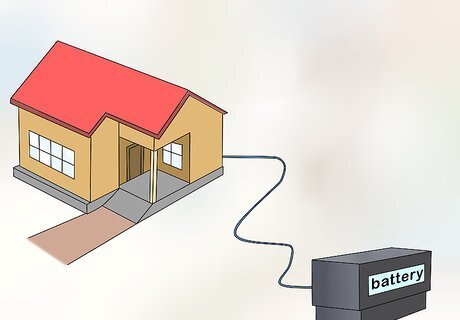

Choose a generator. Your wind turbine needs to be connected to a generator to produce electricity. Most generators are direct current (DC), which means that to use one to provide household current you'll need to connect the generator to a power inverter to produce the alternating current (AC) that household appliances use. You could use an AC motor as a generator, although there may not be sufficient residual magnetism to produce a strong enough electric field. A generator relies on motion, in this case the movement of your blades, and magnetic force to generate electricity. A pre-made generator will be the easiest option for beginners, but tutorials can be found to make your own by searching the internet for "making a wind turbine generator." If you decide to buy a DC generator, look for one rated for high voltage and current and low rotation speed (several hundred instead of several thousand revolutions per minute). You need to generate at least 12 volts over a consistent period of time. Your generator should be connected to a deep-cycle battery bank and charge controller in between the generator and inverter to protect the inverter and battery from power spikes. This will also provide power to the inverter during low-wind periods. Automotive alternators are not recommended as generators. These generally need to spin at much faster speeds than wind turbines can sustain to generate power.

Assembling the Spindle and Spokes of a Vertical Axis Wind Turbine

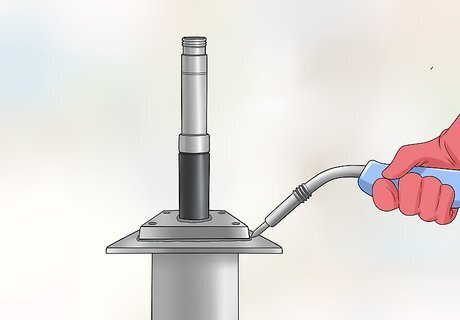

Assemble your spindle. You may need to weld your spindle to your spindle plate, but many wind turbine kits come with this part already welded. If you are constructing your turbine from parts you have purchased or from surplus parts and need to weld, be sure you wear proper safety gear, like a welding visor, welding gauntlets, a welding jacket, and work boots. By putting together your spindle first, you can construct your turbine piece by piece by adding parts one at a time to it. This will likely be the most efficient way to put together your turbine if you are attempting this project on your own.

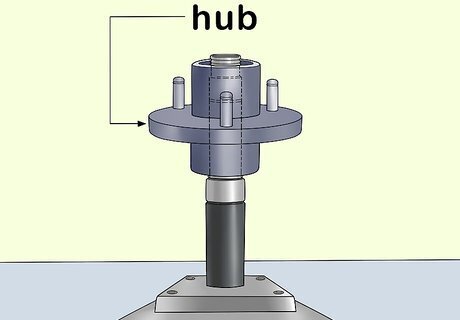

Slide your hub into place on your spindle. To prevent a buildup of friction and deterioration of your spindle/hub, you should place a bearing between the two parts. Fit your bearing over the tapered end of your spindle sticking up from the spindle plate and slide it toward the plate until it comes to a rest at the thicker portion of the spindle. Then slide your hub into place to rest on the bearing so that the studs of your hub face upward. There should be a clearance of about 4" (10.2 cm) between your spindle and the bearing. In high force winds, your turbine may flex, causing the blades to his, and damage, your spindle. If you don't have a kit and are building your hub from scratch, you might consider using a 4 on 4 trailer hub. This can be bought at most stores that carry trailer supplies, like your local automotive parts store.

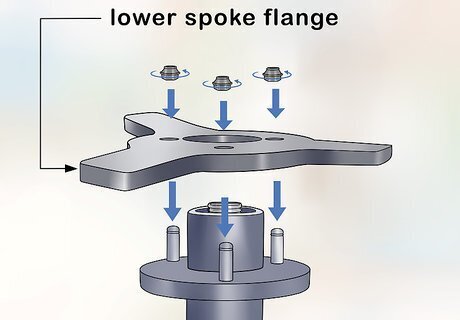

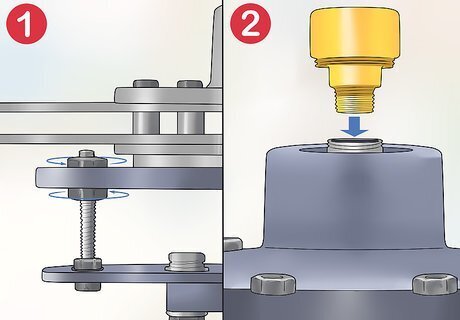

Attach the lower spoke flange to your hub. The flange should have holes for the studs of your hub to slide through, with protruding tabs to which you'll attach each of your spokes. Line up your flange with the studs of your hub and maneuver it into place. Once your flange is resting evenly on your hub, fasten it into place with lug nuts, tightening the nuts first by hand and then more firmly with a socket wrench.

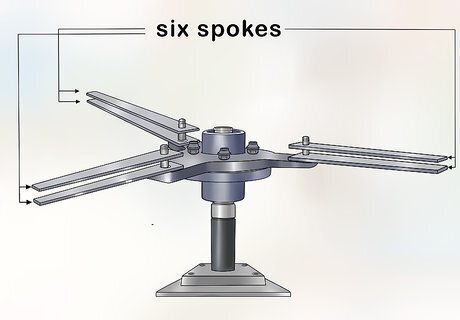

Connect your spokes. You will have two sets of spokes per blade of your turbine, giving you a total of six spokes for a three bladed turbine. You'll need bolts to connect your spokes to the tabs of your lower flange and spacers to separate the lower spokes from the upper ones. Then: Slide a bolt through a hole in one of the flange tabs, fit your spoke onto the bolt, apply the spacer to the bolt, fit your second spoke into place on the bolt, and sandwich the spokes and spacer into place with your upper flange. Your lower and upper flange should be the same shape, with the same number of spoke attachment tabs. Screw the bolt into the upper flange with your hand to keep the flange in place, then fasten the other bolts for your first set of spokes. Repeat this process for all of your spokes. Once all your spokes are sandwiched between your lower and upper flanges, you should use a socket wrench to tighten your bolts. Once the bolts are tightened, your lower and upper flange and spokes should be sturdy and able to spin easily along with the hub on your bearing. Since your turbine assembly will be exposed to consistent force from the wind and other environmental factors, you'll want your bolts to connect your spokes firmly. To guarantee a good connection, you should use a thread locking compound, which will be available at most hardware stores.

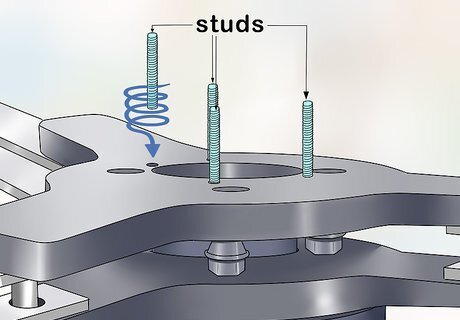

Attach four studs to your upper flange. These studs should be threaded and each stud should be 2/8" (6 cm) long and ¼" (.635 cm) thick. You may need to use a hack saw to cut a threaded rod with this thickness to the correct length. Then, screw your studs in place by hand into the top of your upper flange so that each screw is equally distributed around the spindle shaft. Only screw the studs into the flange far enough so that each stud is upright and sturdy. All studs should stick out of the flange an equal distance. If you use a hacksaw to cut a threaded metal rod, be careful not to damage the threading when you do so. Damaged threading could result in you not being able to fasten parts into place correctly. You'll want these studs to be sturdily attached, much like the bolts you used for your spokes. To this end, you should use a thread locking compound on your studs.

Mounting the Magnets of a Vertical Axis Wind Turbine

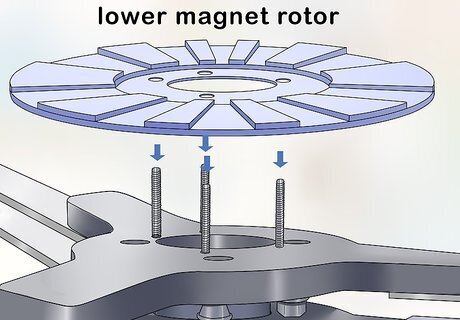

Place your lower magnet rotor onto the studs. You can either make your upper and lower magnet rotors with a rotor plate, epoxy, and 2" by 1" by ½" neodymium magnets, or you can buy this part prefabricated as part of a wind turbine kit or from a wind turbine part manufacturer. With the magnets facing up, fit the bottom plate of your magnet rotor onto the four studs you have fastened to your flange. Whether you make your own or use a kit-made magnet rotor, always be careful when handling individual magnets or the magnet rotor plates. The magnetic forces of these are very strong and can cause serious injury if not handled with caution. Neodymium magnets are fairly brittle. You'll need 24 of these, 12 for your top magnet rotor and 12 for the bottom one, but you might want to purchase extra in case one breaks during construction of your plate. These magnets are available for purchase online.

Make a magnet rotor, if necessary. If you are using a kit that came with a magnet rotor plate, you will only need to fit the plate onto the studs as described previously. For a homemade magnet rotor, you'll want your magnets equally distributed around the edge of your rotor. To prevent misplacing a magnet and potentially ruining your rotor, draw a magnet placement template on card stock or paper. Your template will occupy the middle of your rotor where the magnets will not be. Lines extending from the center to the edges of your template will indicate where magnets should be placed on the rotor. Tape can be used to hold your template in place and example templates can be found online. You should mark the polarity of your magnets before you begin placement. This can be done with a marker. If your magnets get jumbled together and you cannot tell the polarity, make a tester by gluing a weak magnet to a popsicle stick. Pass the "N" polarity side of your tester over the neodymium magnet. If you feel a push, the magnet is the same polarity. If you feel a pull, the polarity of the magnet you are testing is opposite. Use a pea-sized amount of epoxy when mounting your magnets. This should be applied to the bottom of each magnet before placing. Being careful to keep your fingers from between the magnet and rotor, slowly move the magnet to corner of the rotor plate. The magnet should grab onto the plate, and then you can slide it into the correct position using your template.

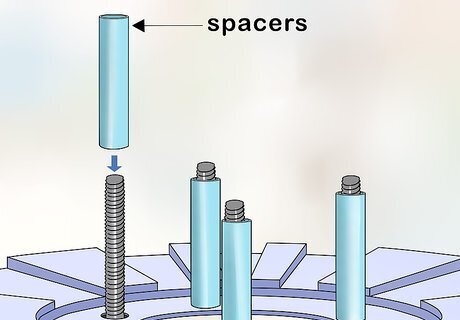

Place spacers on your studs. You can use /8" (.375 cm) metal tubing cut into 1¼" (3.175 cm) long segments to create your spaces. You should cut these as accurately as you can. Slide your spacers over the studs sticking up from your magnet rotor. Spacers that are unequal in length could create a slanted position for your upper magnet disk. This could be dangerous, and could also negatively impact the efficiency of your turbine. There should be a little over an inch (2.5 cm) of stud clearance above your spacers. This will allow hex nuts to fasten your upper magnet rotor, and all parts in between, together.

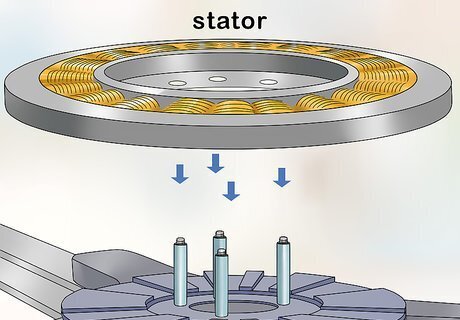

Place your stator on top of your lower magnet rotor. A stator is a series of coiled wires that are a vital part of any generator. It can be bought as part of a wind turbine kit, from a wind turbine part manufacturer, or can be made on your own.The studs surrounding the central spindle shaft should stick up through the center of the stator, which should be centered with respect to the central spindle shaft. Your stator will need three groupings of three coils of 24 gauge copper wire, with each coil having 320 windings of the copper wire. This can be time-consuming and difficult to make. If you decide to make your own stator, an online search for "how to make a wind turbine stator" will walk you through the process.

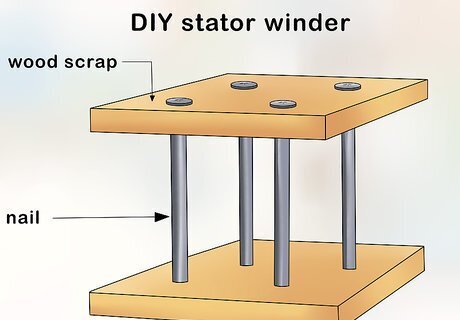

Make a stator winder for homemade stators. You can construct a stator winder from scrap wood and nails. Connect two pieces of plywood with four nails so that there is a gap of about 1" (2.5 cm) between the two pieces of wood. Your nails should be spaced in a rectangular pattern that corresponds to the dimensions of your magnets. Then you can more easily wind the copper wire for your stator. When making your own stator, be sure to keep track of the beginning and ending of your stator coils. Each coil must be wound in the same direction. You might want to consider putting a colored piece of electrical tape on the beginning of each end every coil. So that your coils don't unwind once you've finished, you should be taped together with electrical tape and secured with two-part epoxy. Allow your epoxy (and stator) to cure on wax paper for however long is indicated on your epoxy label.

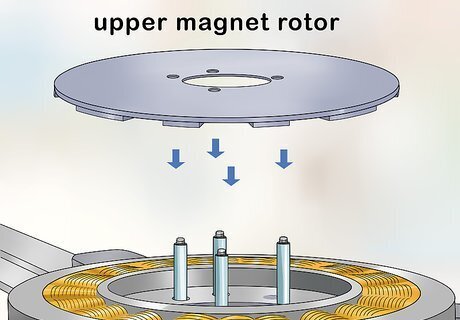

Place your upper magnet rotor. Use extreme caution; this is one of the most dangerous parts of the construction of your wind turbine. Stack four boards on your stator to either side of your central spindle, with the baseboards being thicker and your top boards thinner. 2 by 4 boards work well for upper boards. Hold your upper magnet rotor so that your fingers are in the gap between your stacked boards, and slowly lower your upper rotor toward the lower one. Attempt to line up your upper rotor with the studs as you do so. The magnetic field should grab the upper disk and pull it onto the boards you have placed. Then, lower the upper magnet rotor onto the studs by sliding out your boards one at a time. First remove one upper board, then the other. Repeat this process with your lower boards to maneuver your upper magnet rotor into place. Then screw hex nuts onto your studs to fasten the rotor. Once this is complete, your upper rotor should be resting on the spacers with a small amount of the studs protruding from the top of it. You may have to wiggle your boards back and forth to work each free of the upper magnet rotor. The magnetic force will be very powerful.

Finishing Your Turbine Assembly

Remove the assembly from the spindle. Next you will be connecting your spindle to your tower. Doing so while your turbine assembly is attached to the spindle can be quite difficult to manage. Then you'll need to invert your assembly hub-upwards to complete your turbine. Pull the assembly (including the hub, spokes, magnet rotors, stator, and all associated parts) off the spindle with an upwards motion. Then place your assembly on your work area, hub-side facing up.

Weld your spindle flange to your tower. If you have a kit, these parts were likely provided, but a metal plate attached to the top of a thick, sturdy metal pipe should suffice for your tower. Be sure that your pipe can withstand the forces the wind will be exerting on your wind turbine. Your tower will need to be installed at a sturdy location. You might want to pour a concrete slab into which you install your tower to give it additional stability.

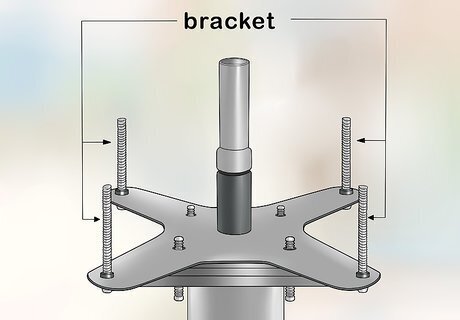

Install a bracket for your spindle and stator. The bracket should fit over your spindle like a collar. You should then bolt the bracket into place, attaching the bracket to the tower. Then cut a /8" (.375 cm) threaded rod into four 4½" pieces. Use a thread locking compound first, and then use nuts and washers to attach these to the outside of your bracket facing upwards. Nuts should be placed on the /8" (.375 cm) threaded rod studs about ¾ of the way from the top of the rod. These nuts will allow you to adjust the position of your stator while the rod holds it in place.

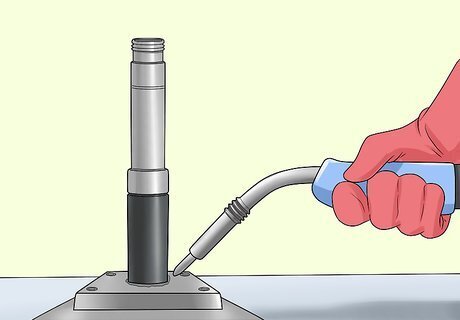

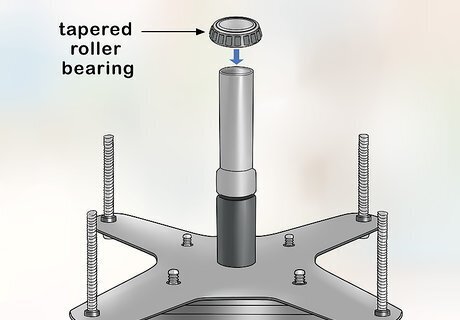

Place a tapered roller bearing on the spindle. Before you do so, you should smear a liberal amount of general purpose bearing grease onto your bearing. After greasing, simply slide your tapered bearing onto the spindle so it rests at the base of your spindle. The greasing process is most easily done with your fingers. Have some paper towel or a work rag close by to wipe your fingers clean once the bearing is greased and placed.

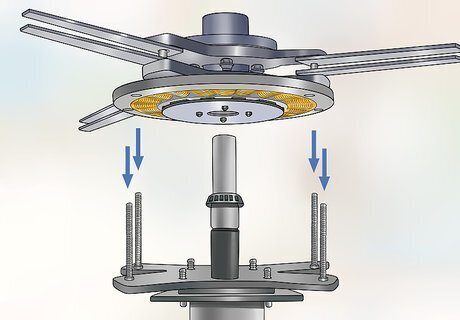

Attach the main assembly of your turbine. Lift the main assembly so that the hub is facing upwards and settle it onto the spindle with the tapered bearing beneath. The mounting holes in your stator should line up with the /8" threaded rod studs that you fastened to your bracket. Once the assembly is in place, you'll need to put another tapered bearing into the cap of your hub. Grease the bearing with general purpose bearing grease. Atop your bearing you'll need to fasten a castle nut. The castle nut should be screwed into place with your fingers. When you cannot turn the nut easily, unscrew it until the gap in the castle nut aligns with the hole in the shaft of your spindle. Slide a cotter pin in this hole and use pliers to bend the legs of the pin to lock the castle nut into place.

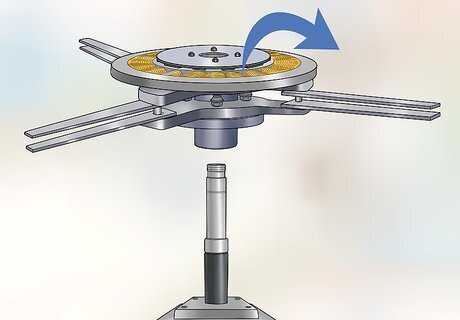

Fasten your stator and complete the turbine with a grease cap. Use one hex nut per rod to lock the stator firmly into place on your assembly. Then, using two wrenches, adjust the hex nuts sandwiching your stator until it is directly in between the magnet rotors. Once your stator is positioned, all you need to do is add a grease cap to the top of your hub and your turbine is complete.

Installing Turbine Electrical Components

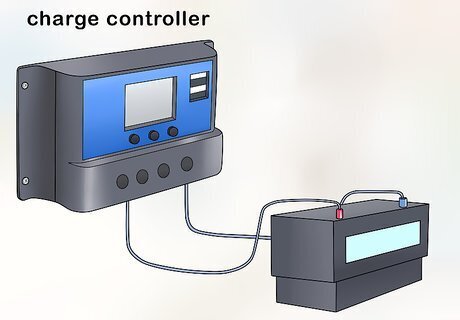

Connect a charge controller to the battery or circuit. Connecting the charge controller to the battery before connecting it to the wind turbine will prevent power spikes from forming. This, in turn, will prevent damage to your equipment.

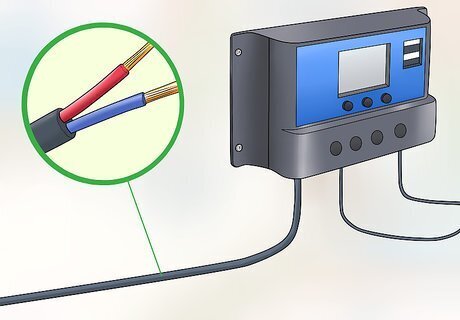

Connect insulated wire to the charge controller. This wire will transfer power from the generator to the charge controller. From there the electricity will pass into a battery or circuit. Your wire should be like that found in power cords, with two lengths of wire bound in similar insulation. You can use an old extension cord with the plugs removed, if you wish.

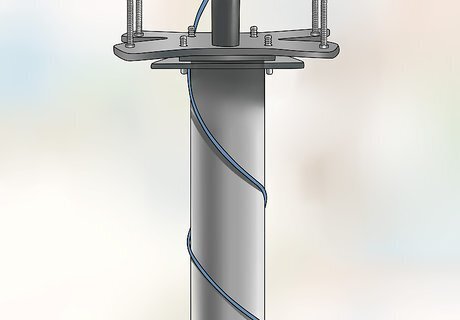

Thread insulated wire through the base and tower shaft. Insert the wire into the tower and up to the turbine assembly. You may need to use a string line or fish tape to help you thread the wire through the tower. Then, connect the wires to your generator.

Connect to a battery or circuit. Now that you have your generator tied in to a charge controller and through the base of your tower, you're ready to tie in the line from your turbine. Whenever tying in an external electrical source to your main home circuit, you should consult a professional electrician. Many areas required a licensed professional to handle this kind of wiring.

Comments

0 comment