views

Punching Down a Jack

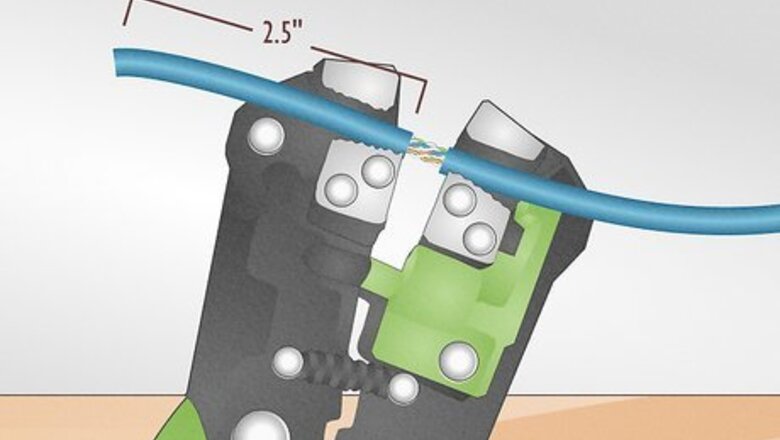

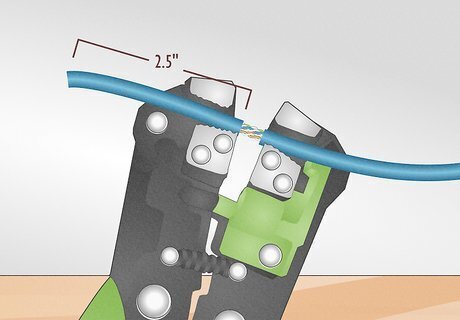

Strip back the cable jacket. You should leave about 2.5 inches (6 cm) at the end of the cable. Insert the cable into the cable stripping tool or modular crimping tool and spin it around a few times. You should see that the jacket is cut. Remove the jacket. Stripping back the cable will help you remove the jacket to expose enough of the cable so you can separate it.

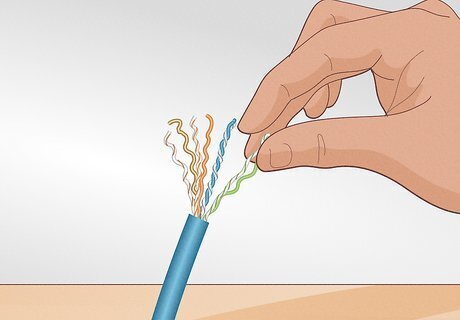

Expose the wires. You should have a few inches of exposed cable once you remove the cable jacket. Gently pull away the wire pairs from the center of the cable so they fan out. Separate the wire pairs by twisting in a counterclockwise motion. Try to straighten the ends as much as you can since this can make them easier to terminate.

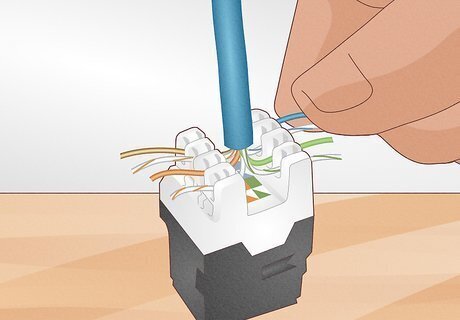

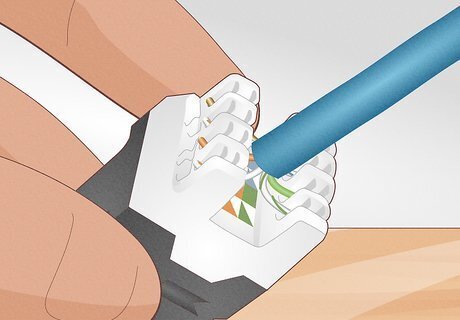

Place the cable wires in the jack. Take the protective cover off the top of the jack and set the cable into the block of the jack. Insert each wire (conductor) into its own separate slot, making sure that the wire matches the A or B configuration. The conductor wires should be extending out of the jack. Consider whether or not you want to use the T568A or T568B wiring scheme. The T568B is becoming more popular since it can be used with older color codes as well as newer codes.

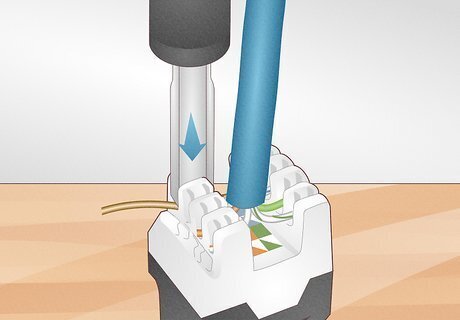

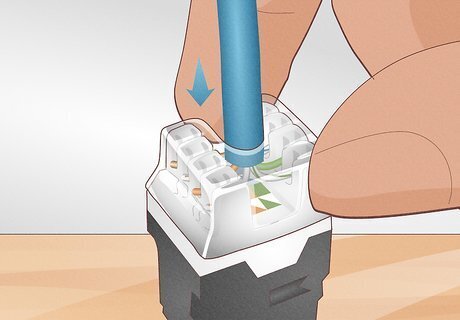

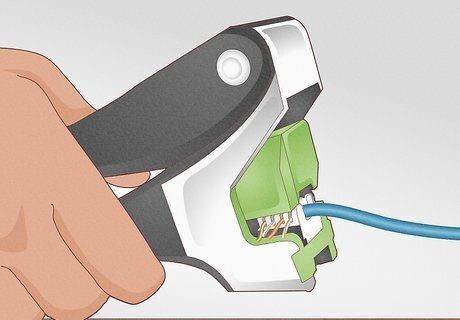

Terminate the conductor wires. Take your punch down tool and press it down on the conductor wires to cut them. The angled (cut) part of the blade should come into contact with the shoulder (the long sturdy side of the jack). This will also make sure the wires that are cut are flush with the jack. Be sure to punch straight down and not at an angle. This will prevent the jack from bending. You should hear a loud click when you punch down. This just means that you've terminated the wire correctly.

Inspect the wires. Once you've finished terminating the wires, look at each wire to make sure there is no overhang out the side of the jack. You should also make sure that the edge of the cable jacket is near the base of the jack and the wires you just terminated. The wires should be securely in place. If you notice wires sticking out the side, take a wire cutter and carefully trim the wire so that it's flush with the jack.

Place a dust cap on the jack. Snap the dust caps in place so that the wires are protected. This will keep the connection secure and can prevent strain on the wires. You can easily remove the dust cap if you need to make changes to wiring later. Simply pop off the dust cap using a flat-head screwdriver inserted into the indentation on the side. If you can't set the dust caps back on the jack, your wires may not be seated correctly. Check the wires again to make sure they are secure and trimmed.

Choosing a Punch Down Tool

Find a basic hand-powered punch down tool. If you'll only occasionally be terminating wires, you can find a simple punch down tool that relies on pressure to trigger a cutting mechanism. These are usually the least expensive and you can purchase replacement blades if they become dull. 110, 66, and krone are the main different types of punch down tools. The 66 punch down tool is mainly used to terminate wires for Cat3, while the 110 punch down tool is used for terminating blocks for ethernet cables. The krone punch down tool is great for installing and terminating Cat3, Cat5, Cat6.

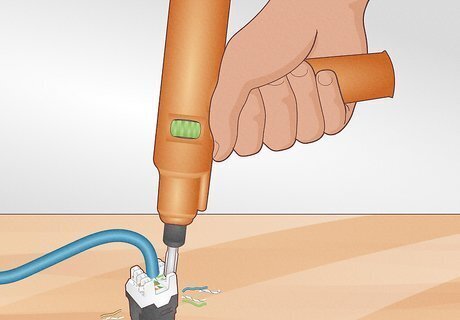

Consider buying a battery-powered punch down tool. If you'll be terminating lots of wires or need to do it quickly, you may want to use a battery-powered punch down tool. These usually come with lithium batteries that don't require much charging. You can choose the voltage for your punch down tool as well as whether or not you'd like to buy replacement blades. You may want to buy the extra blades if you'll be terminating a lot of wires.

Get a multi-wire punch down tool. You might find that you're still terminating so many wires that a standard punch down tool can't keep up with the work. Multi-wire punch tools work by terminating several pairs of twisted wires so you can terminate more wire more quickly. Multi-wire punch down tools are also more efficient than standard punch down tools. They can also decrease hand fatigue which is more common in standard punch tools.

Comments

0 comment